-

Bahasa Indonesia

-

English

Oleh: Vincent Gaspersz,

Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- American Production and Inventory Control Society (www.apics.org) Certified in Production and Inventory Management (CPIM), Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- American Society for Quality (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Quality Improvement Associate (CQIA), and Certified Six Sigma Black Belt;

- International Quality Federation (www.iqf.org) Certified Six Sigma Master Black Belt (CSSMBB);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Auditor (CMSA), Certified Management System Practitioneer (CMSP), Certified Management System Specialist (CMSS), and Certified Management System Lead Specialist (CMSLS).

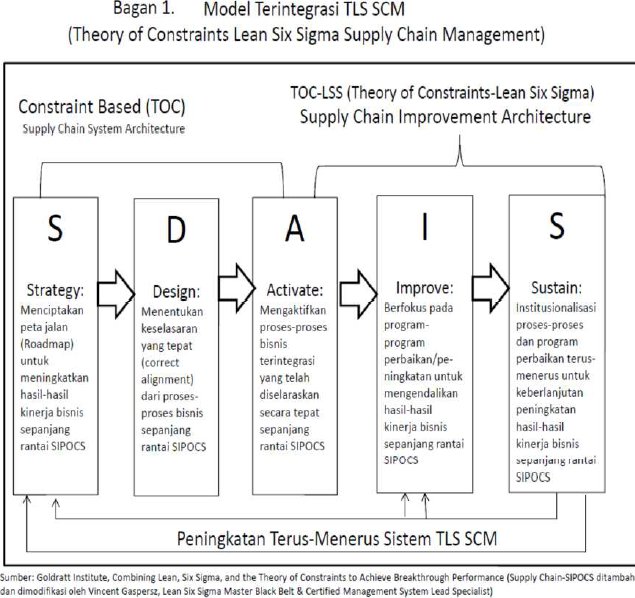

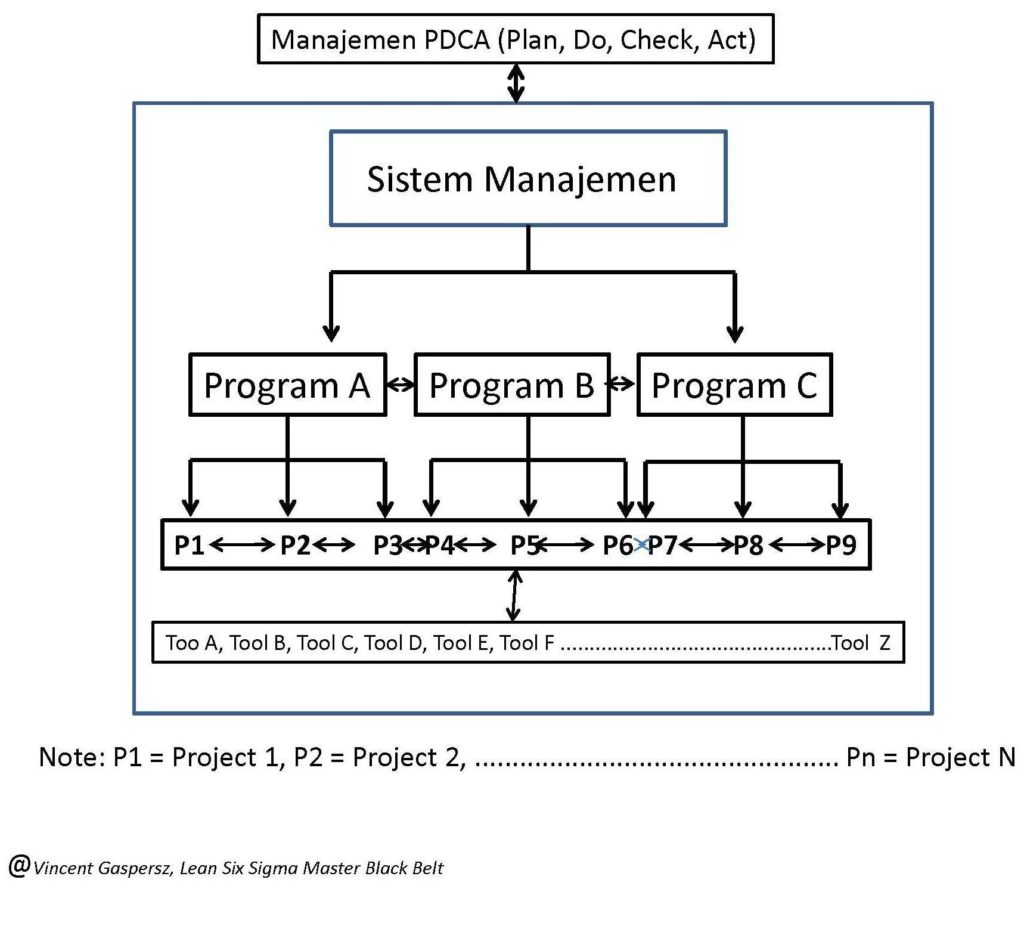

Model terintegrasi Theory of Constraints Lean Six Sigma Supply Chain Management (TLS SCM) menggunakan langkah-langkah SDAIS (lihat Bagan 1 terlampir di atas), di mana langkah S (Strategy), D (Design) and A (Activate) merupakan Constraints-based (TOC Supply Chain System) Architecture, sedangkan langkah I (Improve) and Sustain termasuk TLS (Theory of Constraints Lean Six Sigma) Supply Chain System Improvement Architecture.

Penjelasan Model SDAIS secara singkat diberikan di bawah ini.

Strategy: Menciptakan peta jalan (Roadmap) untuk meningkatkan hasil-hasil kinerja bisnis sepanjang rantai SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). Output dari strategi yang baik adalah jelas, kinerja yang disepakati, dan peta jalan (road map) untuk meningkatkan hasil-hasil dari organisasi (bisnis maupun publik). Fokus utama adalah mengoptimumkan kinerja total supply chain system.

Design: Menentukan keselasaran yang tepat (correct alignment) dari proses-proses bisnis sepanjang rantai SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). Pada tahap ini pemimpin operasional/fungsional dan ahli yang berkaitan dengan topik yang relevan mendesain operasional sistem untuk menyelaraskan proses-proses kerja organisasi agar mencapai hasil-hasil kinerja bottom-line seperti: profitabilitas yang meningkat bagi organisasi bisnis dan/atau pelayanan publik yang meningkat pada kendala anggaran yang terbatas bagi organisasi publik. Selama proses desain hal-hal utama yang dilakukan adalah mengkonfigurasikan ulang kebijakan-kebijakan, pengukuran-pengukuran, peran dan tanggung jawab, serta system informasi yang terkait dengan solusi dan eksekusi theory of constraints (TOC) sebagai sistem manajemen yang telah terbukti unggul.

Activate: Mengaktifkan proses-proses bisnis terintegrasi yang telah diselaraskan secara tepat sepanjang rantai SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). Selama proses Activate, kebijakan-kebijakan baru, pengukuran-pengukuran baru, peran dan tanggung jawab baru, system-sistem informasi dan berbagai teknik manajemen yang relevan diimplementasikan untuk membuat sistem operasional sepanjang supply chain berfungsi dengan baik.

Constraint-based system architecture akan menghasilkan sistem di mana proses-proses organisasi (bisnis atau publik) didesain, diselaraskan, dan dioperasikan dalam keadaan stabil, berulang, dan dapat diprediksi sebagai persyaratan mutlak untuk perbaikan terus-menerus pada proses-proses yang stabil dan dapat diprediksi dalam supply chain system.

Sekali supply chain system ditetapkan dan memberikan hasil-hasil yang dapat diprediksi dalam situasi stabil, maka perbaikan atau peningkatan kinerja supply chain (supply chain performance) dapat dilakukan terus-menerus. Dalam situasi ini, maka TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain System) improvement mulai bekerja dan dikendalikan oleh manajemen profesional.

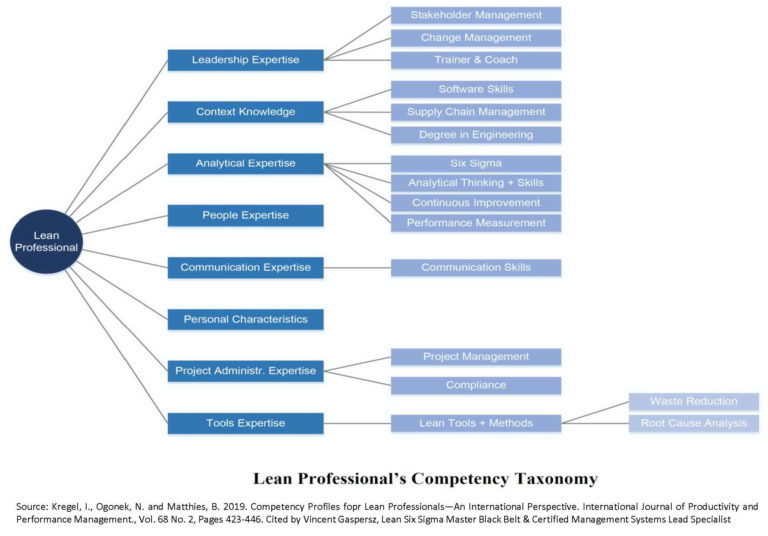

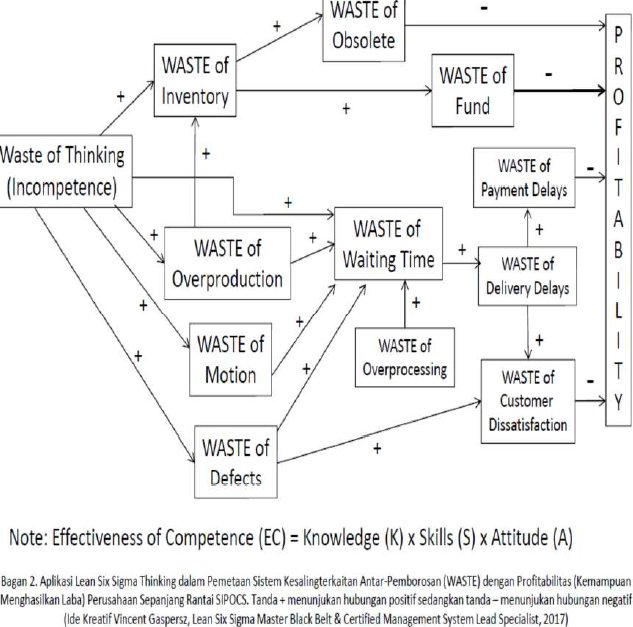

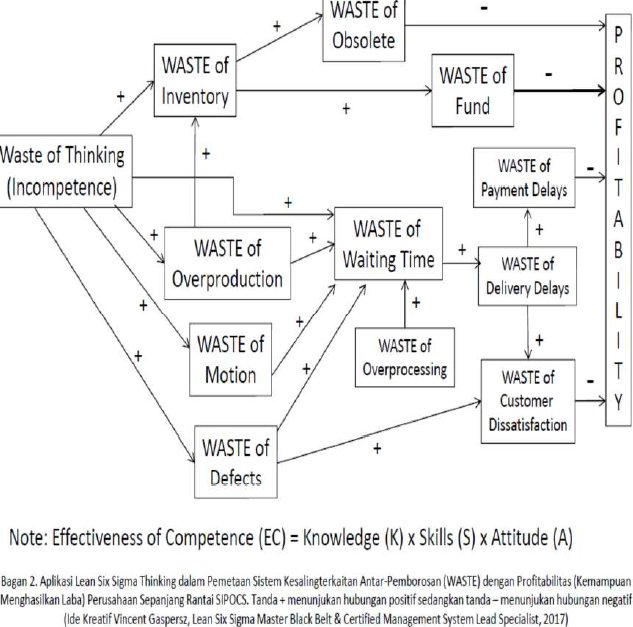

Improve: Berfokus pada program-program perbaikan/peningkatan untuk mengendalikan hasil-hasil kinerja bisnis sepanjang rantai SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). Dampak program-program perbaikan kinerja menggunakan Lean Six Sigma tools untuk menghilangkan berbagai WASTE yang telah dipetakan oleh Vincent Gaspersz dalam kerangka sistem (lihat Bagan 2) akan dievaluasi berdasarkan kemampuan meningkatkan Throughput (T), mengurangi Inventory (I), and Operating Expenses (OE) yang merupakan elemen-elemen utama dari Throughput Accounting system. Kerangka kerja Throughput Accounting system ditunjukan dalam Bagan 3.

Sustain: Institusionalisasi proses-proses dan program perbaikan terus-menerus untuk keberlanjutan peningkatan hasil-hasil kinerja bisnis sepanjang rantai SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). Manajemen organisasi (bisnis atau publik) secara terus-menerus meninjau-ulang (review) hasil-hasil indicator kinerja kunci (KPIs = Key Performance Indicators), menerapkan dan menginstitusionalisasikan kebijakan-kebijakan manajemen, perilaku dan tanggung jawab untuk menjamin peningkatan hasil-hasil secara berkelanjutan dalam kerangka aplikasi TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain Management).

Menggunakan model SDAIS dalam TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain Management) akan menghindarkan manajemen organisasi dari praktek-praktek acak (random practices) dalam membangun sistem-sistem manajemen modern.

Salam SUCCESS.

Referensi

- Gharajedaghi , J. 2011. Systems Thinking: Managing Chaos and Complexity A Platform for Designing Business Architecture, 3rd ed., Elsevier, New York, 374 pages.

- Goldratt Institute. Combining Lean, Six Sigma, and the Theory of Constraints to Achieve Breakthrough Performance.

- Nelson, B and Bob Sproull, 2016, Focus on Leverage: The Critical Methodology for Theory of Constraints, Lean, and Six Sigma (TLS), CRC Press, Florida, 372 pages.

- Pirasteh, R. and Robert E. Fox, 2011., Profitability With No Boundaries: Optimizing TOC, Lean, Six Sigma Results (Focus, Reduce Waste, Contain Variability), ASQ Quality Press, Wisconsin, 374 pages.

- Schonsleben, P. 2015, Integral Logistics Management: Operations and Supply Chain Management Within and Across Companies, CRC Press, Florida, 844 pages.

- Sproull, B and Bruce Nelson, 2015., Epiphanized: A Novel on Unifying Theory of Constraints, Lean and Six Sigma, CRC Press, Florida, 414 pages.

- Srinivasan, M. M., 2012. Building Lean Supply Chains with the Theory of Constraints., McGraw-Hill, New York, 358 pages.

- Jacobs, F.R., William L. Berry, D. Clay Whybark, and Thomas E. Vollman, 2011, Manufacturing Planning and Control for Supply Chain Management: APICS/CPIM Certification Edition, McGraw-Hill, New York, 577 pages

Latest Industrial Management System Development: Theory of Constraints Lean Six Sigma Supply Chain Management (TLS SCM)

By: Vincent Gaspersz,

Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- American Production and Inventory Control Society (www.apics.org) Certified in Production and Inventory Management (CPIM), Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- American Society for Quality (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Quality Improvement Associate (CQIA), and Certified Six Sigma Black Belt;

- International Quality Federation (www.iqf.org) Certified Six Sigma Master Black Belt (CSSMBB);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Auditor (CMSA), Certified Management System Practitioneer (CMSP), Certified Management System Specialist (CMSS), and Certified Management System Lead Specialist (CMSLS).

The Integrated Theory of Constraints Lean Six Sigma Supply Chain Management (TLS SCM) model uses the steps of SDAIS (see Chart 1 above), where S (Strategy), D (Design) and A (Activate) belong to Constraints-based (TOC Supply Chain System) Architecture, while step I (Improve) and Sustain belong to TLS (Theory of Constraints Lean Six Sigma) Supply Chain System Improvement Architecture.

The brief explanation of the SDAIS Model is given below.

Strategy: Creating a Roadmap to improve business performance results along the SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders) chain. The outputs of a good strategy are clear, agreed performance, and a road map to improve the results of the organization (business as well as public). The main focus is to optimize the total performance of the supply chain system.

Design: Determining the correct alignment of business processes along the SIPOCS chain (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders). At this stage, operational/functional leaders and experts relating to relevant topics design the operational systems to align organizational work processes to achieve bottom-line performance results such as: increased profitability for business organizations and/or improved public services on limited budget constraints for public organizations. During the design process, the main things to be done are to reconfigure the policies, measurements, roles and responsibilities, as well as information systems related to the solution and execution of theory of constraints (TOC) as proven superior management system.

Activate: Enabling integrated business processes that are properly aligned along the SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders) chain. During the Activate process, new policies, new measurements, new roles and responsibilities, information systems and various relevant management techniques are implemented to make the operational systems along the supply chain to function properly.

Constraint-based system architecture will produce systems in which organizational processes (business or public) are designed, harmonized, and operated in a stable, repetitive, and predictable state as the absolute requirement for continuous improvement on stable processes and can be predicted in the supply chain system.

Once a supply chain system is established and it delivers predictable results in a stable situation, then supply chain performance improvements can be made continuously. In this situation, the TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain System) improvement begins to work and is controlled by professional management.

Improve: Focusing on improvement programs to control business performance results along the SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders) chain. The impact of performance improvement programs using Lean Six Sigma tools to remove various WASTE that has been mapped by Vincent Gaspersz in the system framework (see Chart 2) will be evaluated based on the ability to increase throughput (T), reduce Inventory (I) and Operating Expenses (OE ), which are the main elements of the Throughput Accounting system. The Throughput Accounting system framework is shown in Chart 3.

Sustain: Institutionalizing processes and continuous improvement programs for the sustainability of improved business performance results along the SIPOCS (Suppliers-Inputs-Processes-Outputs/Outcomes-Customers-Shareholders/Stakeholders) chain. The organization’s management (business or public) continually review key performance indicator results (KPIs), apply and institutionalize management policies, behaviors and responsibilities to ensure sustainable improved results within the framework of TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain Management) applications.

Using the SDAIS model in TLS SCM (Theory of Constraints Lean Six Sigma Supply Chain Management) will avoid organizational management from random practices in building modern management systems.

Best Regards for SUCCESS.

References

- Gharajedaghi , J. 2011. Systems Thinking: Managing Chaos and Complexity A Platform for Designing Business Architecture, 3rd ed., Elsevier, New York, 374 pages.

- Goldratt Institute. Combining Lean, Six Sigma, and the Theory of Constraints to Achieve Breakthrough Performance.

- Nelson, B and Bob Sproull, 2016, Focus on Leverage: The Critical Methodology for Theory of Constraints, Lean, and Six Sigma (TLS), CRC Press, Florida, 372 pages.

- Pirasteh, R. and Robert E. Fox, 2011., Profitability With No Boundaries: Optimizing TOC, Lean, Six Sigma Results (Focus, Reduce Waste, Contain Variability), ASQ Quality Press, Wisconsin, 374 pages.

- Schonsleben, P. 2015, Integral Logistics Management: Operations and Supply Chain Management Within and Across Companies, CRC Press, Florida, 844 pages.

- Sproull, B and Bruce Nelson, 2015., Epiphanized: A Novel on Unifying Theory of Constraints, Lean and Six Sigma, CRC Press, Florida, 414 pages.

- Srinivasan, M. M., 2012. Building Lean Supply Chains with the Theory of Constraints., McGraw-Hill, New York, 358 pages.

- Jacobs, F.R., William L. Berry, D. Clay Whybark, and Thomas E. Vollman, 2011, Manufacturing Planning and Control for Supply Chain Management: APICS/CPIM Certification Edition, McGraw-Hill, New York, 577 pages