“Ilmu tentang Lean Six Sigma yang Secara Susah Payah Dipelajari dan Diterapkan Sejak Tahun 2003 oleh VG TELAH Memperoleh Pengakuan Internasional Dengan Diterbitkan ISO 18404:2015 ini”

Oleh: Vincent Gaspersz, Lean Six Sigma Master Black Belt and Certified Management Systems Lead Specialist

——————–

• APICS (www.apics.org) Certified in Production and Inventory Management (CPIM), Certified in Production and Inventory Management Fellow (CPIM-F), Certified Supply Chain Professional (CSCP), Certified Supply Chain Professional Fellow (CSCP-F),

• International Quality Federation (www.iqf.org) Six Sigma Master Black Belt (SSMBB),

• American Society for Quality (www.asq.org/cert) Certified Six Sigma Black Belt (CSSBB), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Improvement Associate (CQIA)

• Registration Accreditation Board (www.exemplarglobal.org) Certified Management Systems Lead Specialist (CMSLS),

• Insinyur Profesional Utama (IPU) – Badan Kejuruan Teknik Industri- Persatuan Insinyur Indonesia (BKTI – PII)

• Asean Engineer Register (AER No. 10084), Asean Federation of Engineering Organizations (AFEO)

• Senior Member of the American Society for Quality

(Member #: 00749775), International Member of the American Production and

Inventory Control Society/Association for Supply Chain Management (Member #:

1023620), and Senior Member of the Institute of Industrial and Systems

Engineers (Member #: 880194630).

———————–

Pengantar

Judul ISO 18404:2015 adalah: “Quantitative methods in process improvement — Six Sigma — Competencies for key personnel and their organizations in relation to Six Sigma and Lean implementation”

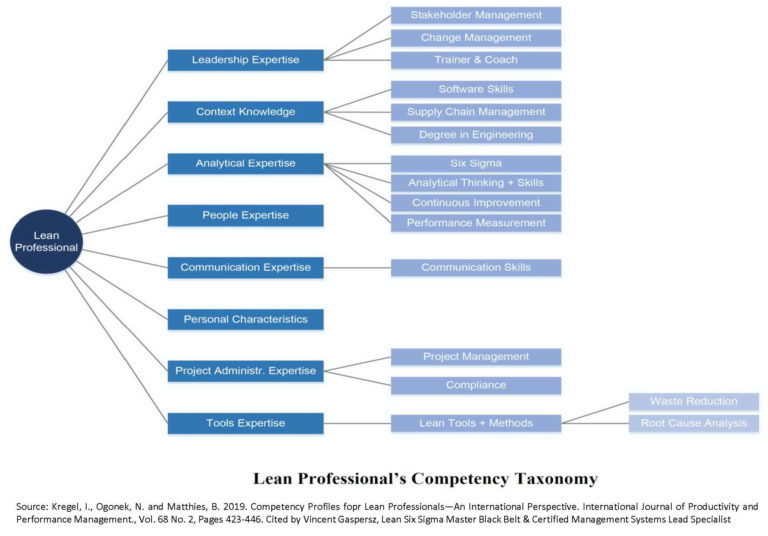

ISO 18404:2015 mendefinisikan kompetensi-kompetensi (unit-unit kompetensi) untuk pencapaian level kompetensi spesifik berkenaan dengan Six Sigma, Lean, dan “Lean & Six Sigma” pada individu, misal: Praktisi Green Belt, Black Belt, Master Black Belt, dan Praktisi Lean serta organisasi mereka yang akan dan/atau sedang menerapkan Manajemen Six Sigma, Lean, atau “Lean Six Sigma”. Kompetensi Yellow Belt tidak termasuk dalam ISO 18404: 2015, juga ISO 18404: 2015 tidak membahas tentang Desain untuk Six Sigma (Design for Six Sigma).

Standar Internasional ini menetapkan dan mengklarifikasi kompetensi yang diperlukan untuk personel dan organisasi yang akan dan/atau sedang menerapkan Six Sigma, Lean, dan “Lean & Six Sigma”. Karena ambiguitas dari banyak kombinasi Lean dan Six Sigma, saat ini disebut “Lean Six Sigma”, maka Standar Internasional ini akan menggunakan istilah “Lean & Six Sigma”. Sebelum ini, belum ada standar universal tentang apa yang merupakan kompetensi personel Green Belt, Black Belt, Master Black Belt atau apa yang diperlukan dalam organisasi yang menggunakan pendekatan Six Sigma, Lean, atau “Lean and Six Sigma” ini sebagai standar internasional.

Misalnya, jika sebuah organisasi mengiklankan mencari seorang Six Sigma Black Belt, maka bagaimana mereka bisa meyakini dengan tingkat kemampuan “Black Belt” itu? Jika pemasok mengatakan sedang menggunakan Six Sigma atau mungkin Lean, atau “Lean and Six Sigma”, maka bagaimana pelanggan dapat meyakini akan kemampuan mereka yang sebenarnya? Tujuan mendasar dari Standar Internasional ISO 18404:2015 ini adalah untuk membantu dalam menjawab pertanyaan-pertanyaan tersebut.

Banyak perdebatan telah terjadi pada sifat Six Sigma dan Lean, kesamaan dan perbedaan mereka. Protagonis telah berdebat tentang konten atau isi, tumpang tindih, aplikasi, supremasi, dan tujuan dari dua pendekatan itu. Berbagai kombinasi dari dua pendekatan yang ada, banyak menggunakan judul “Lean Six Sigma”. Six Sigma dan Lean memiliki kesamaan bidang aplikasi, yaitu peningkatan proses. Lean berfokus pada pengurangan atau eliminasi WASTE yang ‘kronis’ dan Six Sigma berfokus pada pengurangan atau meminimumkn variasi yang ada serta meminimumkan dampak negatif dari variasi itu baik secara langsung maupun tidak langsung.

Standar Internasional ISO 18404:2015 ini menetapkan persyaratan kompetensi terpisah untuk implementasi Six Sigma dan Lean; juga menetapkan kerangka kerja kompetensi gabungan untuk “Lean & Six Sigma”. Dalam melakukan hal itu, Standar Internasional ISO 18404:2015 berfokus pada kompetensi (keterampilan dan kemampuan) untuk memberikan manfaat kepada organisasi daripada menentukan tingkat pendidikan spesifik yang diperlukan untuk setiap peran seperti: Yellow Belt, Black Belt, dan Master Black Belt.

Menggunakan Standar Internasional ISO 18404:2015 ini, seorang atau sekumpulan orang calon akan diharapkan untuk menunjukkan bahwa mereka memiliki tingkat kompetensi yang memadai, penggabungan dari pendidikan, pelatihan, keterampilan dan pengalaman yang diperlukan untuk memenuhi peran mereka apakah sebagai: Green Belt, Black Belt, atau Master Black Belt.

Standar Internasional ISO 18404:2015 ini memfokuskan pada implementasi Six Sigma, Lean dan “Lean & Six Sigma” secara terpisah. .

Ruang Lingkup

Standar Internasional ISO 18404:2015 ini mendefinisikan kompetensi (unit-unit kompetensi) untuk pencapaian tingkat kompetensi spesifik berkaitan dengan Six Sigma, Lean, dan “Lean & Six Sigma” pada individu, misal: Praktisi Green Belt, Black Belt, Master Black Belt, dan Lean serta organisasi yang akan dan/atau sedang menerapkan Manajemen Six Sigma, Lean, atau “Lean & Six Sigma”. Yellow Belt tidak termasuk dalam Standar Internasional ISO 18404:2015 ini. Standar Internasional ini juga tidak memasukan Design for Six Sigma.

Seperti biasa, paper atau publikasi dari Lembaga Internasional ISO (International Organization for Standardization) memuat persyaratan internasional yang harus diikuti, apabila kita ingin memperoleh pengakuan internasional. ISO 18404:2015 mencakup sejumlah item berikut (tidak diterjemahkan ke dalam Bahasa Indonesia agar memahami keasliannya).

| Introduction |

| 1. Scope |

| 2. Normative references |

| 3. Terms, definitions, and abbreviated terms |

| 3.1 Terms and definitions |

| 3.2 Abbreviated terms |

| 4. Competency of key personnel in relation to Six Sigma, Lean, and “Lean & Six Sigma” |

| 4.1 Education and training |

| 4.2 Skills and competency |

| 4.3 Experience |

| 5. Adequacy of an organization with regards to its Six Sigma, Lean or “Lean & Six Sigma” approach and deployment |

| 5.1 General |

| 5.2 Adequacy of the organization’s Six Sigma, Lean or “Lean & Six Sigma” strategy |

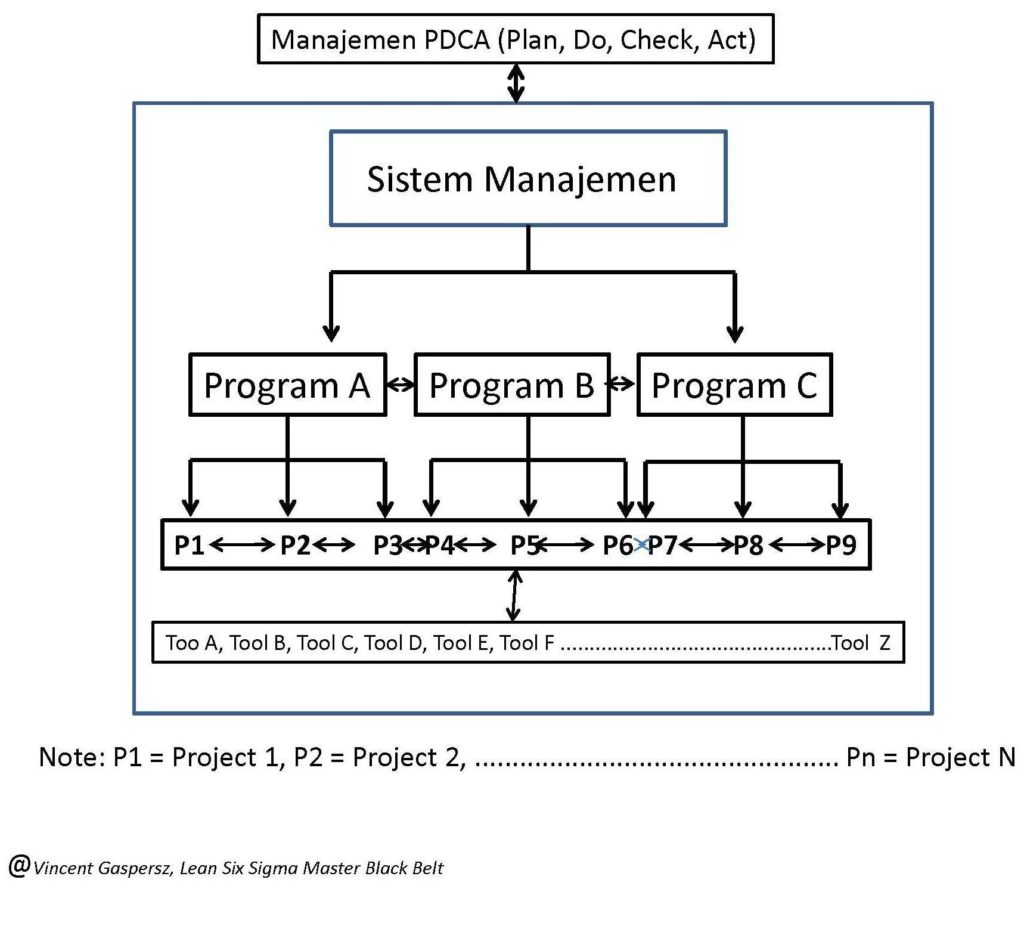

| 5.3 Adequacy of the organization’s Six Sigma, Lean or “Lean & Six Sigma” architecture |

| 5.4 Adequacy of the skills and competencies of the key personnel |

| 5.5 Adequacy and continual improvement of organizational deployment |

| 6. Resource management |

| 6.1 General |

| 6.2 Provision of resources |

| 6.3 Ongoing monitoring of requirements |

| 6.4 Key personnel |

| 6.5 Maintaining competence of key personnel |

| 6.6 Organization |

| 6.7 Maintaining competence of the organization |

| Annex A. Six Sigma |

| A.1 Green Belt |

| A.2 Black Belt |

| A.3 Master Black Belt |

| Annex B. Lean |

| B.1 Lean practitioner |

| B.2 Lean leader |

| B.3 Lean expert |

| Annex C “Lean & Six Sigma” |

| C.1 General |

| C.2 “Lean & Six Sigma” Green Belt |

Beberapa Terminologi Dalam ISO 18404:2015

| 5S | sort, set, shine, standardize, sustain |

| CT | critical to |

| DOWNTIME | defects, overproduction, waiting, non-utilization of talent, transport, inventory, motion, extra-processing |

| EDA | exploratory data analysis |

| HOQ | house of quality |

| OEE | overall equipment effectiveness |

| PDCA | plan, do, check, act |

| PDM | policy deployment matrix |

| SIPOC | supplier-input-process-output-customer |

| SMED | single-minute exchange of die |

| TIM WOOD | transport, inventory, motion, waiting, over-processing, overproduction, defects |

| VOC | voice of the customer |

| VSM | value-stream map |

| WIP | work in progress |

| WORMPIT | waiting, overproduction, rework, motion, processing, inventory, transport |

23 Kompetensi Lean Six Sigma Green Belt (Source: Setec Consulting Group)

Setec Consulting Group telah mengidentifikasi 23 kompetensi inti (unit kompetensi inti) untuk seorang Green Belt (Lean Six Sigma Green Belt), sehingga pemegang sertifikasi kompetensi professional LSSGB dapat menjadikan sebagai panduan untuk mengembangkan keterampilan pada level pemahaman, aplikasi, manajemen dan multiplikasi. Kompetensi ini jauh lebih banyak daripada sekedar memahami alat-alat analisis statistika saja.

- Kemampuan Mengidentifikasi Prioritas dan Manfaat Organisasi

Memahami kepentingan penggunaan kuantifikasi manfaat atau sasaran organisasi unuk memandu seleksi proyek lean six sigma. Menjabarkan identifikasi yang tepat tentang kesempatan-kesempatan organisasi, manfaat-manfaat untuk menghilangkan isu-isu yang menjadi perhatian (pemborosan, cacat, dll) beserta hubungan terhadap sasaran bisnis lokal dan bagaimana seleksi proyek/masalah terkait dengan sasaran ini, Menunjukkan identifikasi dari manfaat-manfaat pada proyek-proyek lean six sigma.

2. Kemampuan Meningkatkan Kinerja Proses Bisnis

Memahami penggunaan lean six sigma untuk mendukung strategi organisasi. Menjelaskan kapan dan di mana lean six sigma akan menjadi pendekatan yang tepat untuk perbaikan atau peningkatan kinerja proses dalam organisasi. Mendemonstrasikan dampak dari lean six sigma pada organisasi.

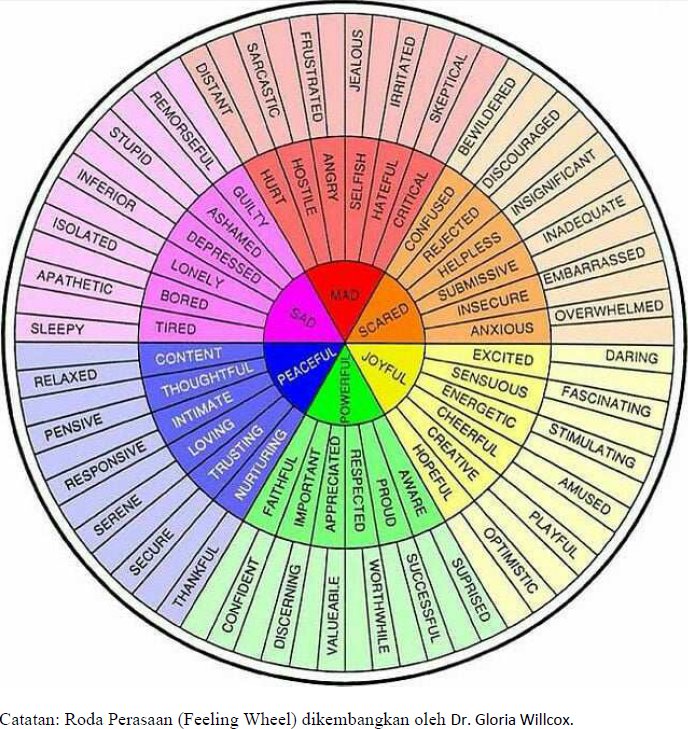

3. Kemampuan Manajemen Perubahan

Memahami peranan dari seorang Lean Six Sigma Green Belt dalam manajemen perubahan dan pentingnya menggunakan pendekatan yang koheren untuk mengelola perubahan. Menjelaskan interaksi antara pemangku kepentingan dan proses perubahan dalam proyek Lean Six Sigma Green Belt dan dampak timbal balik satu sama lain. Menunjukkan partisipasi dan komunikasi perubahan.

4. Kemampuan Akuisisi Data untuk Analisis

Mengidentifikasi dan secara aktif mencari informasi yang tepat dalam berbagai bentuk, memastikan validitas informasi tersebut dan mentransformasikannya menjadi data yang dapat dianalisis dalam Kompetensi No. 22. Menjelaskan perbedaan antara informasi kualitatif dan kuantitatif dan manfaat dari mengukur kinerja. Menjelaskan di mana data dapat ditemukan, bagaimana data itu dikumpulkan dan teknik analisis apa yang mungkin digunakan dalam proyek Lean Six Sigma Green Belt. Menjelaskan di mana atau bagaimana validitas dapat dikompromikan dan tindakan apa yang mungkin diperlukan. Membuktikan implementasi rencana untuk memperoleh data yang sesuai.

5. Kemampuan Mengembangkan Kepemimpinan Diri

Pentingnya mengembangkan keterampilan kepemimpinan dalam diri. Menjelaskan pengembangan kepemimpinan termasuk hal-hal berikut yang sesuai: penilaian diri, pentingnya pelatihan, pentingnya bimbingan, dan rencana pengembangan pribadi.

6. Kemampuan Mengembangkan Kepemimpinan Orang Lain

Pentingnya pengembangan kepemimpinan pada orang lain. (Lihat juga Kompetensi No. 20).

7. Kemampuan Berpikir Kreatif

Memahami kebutuhan menerapkan pendekatan pemikiran kreatif untuk mengejar tujuan proyek Lean Six Sigma Green Belt. Menjelaskan berbagai model berpikir (misal: kreatif dan analitik). Membuktikan penggunaan pendekatan ini selama proyek Lean Six Sigma Green Belt.

8. Kemampuan Berfokus Pelanggan

Memahami bagaimana dan mengapa mendengarkan ‘suara pelanggan’ (Voice of Customer/VoC). Menjelaskan berbagai jenis pelanggan sebagaimana diterapkan pada proyek Lean Six Sigma Green Belt. Mendemonstrasikan penerapan pendekatan ‘fokus pelanggan’. Misalnya, melalui penggunaan yang benar dari peralatan “’rumah kualitas (House of Quality/HoQ)’ dan / atau matriks ‘kritis terhadap’ (Critical To Matrix).

9. Kemampuan Pembuatan dan Pengambilan Keputusan

Memiliki kemampuan pengambilan keputusan dan mengidentifikasi pengambil keputusan. Menjelaskan keadaan di mana pengambilan keputusan diperlukan dalam proyek Lean Six Sigma Green Belt dan tanggung jawab untuk pembuatan dan pengambilan keputusan ini.

10. Kemampuan Keterampilan Kepemimpinan Tim dan Antar-pribadi

Mendukung interaksi yang efektif dengan orang lain termasuk pemangku kepentingan. Bekerja secara efektif dengan orang lain untuk mencapai tujuan. Mengetahui faktor-faktor yang mempengaruhi efektivitas tim, termasuk faktor-faktor seperti gaya kepemimpinan, peran tim, tipe kepribadian. Menunjukkan penggunaan teknik komunikasi yang efektif dalam proyek Lean Six Sigma Green Belt.

11. Kemampuan Memotivasi Orang Lain

Memahami mengapa penting untuk memotivasi individu dan tim agar maju menuju tujuan. Mengetahui kemungkinan motivasi seperti mengidentifikasi pendorong individu, menciptakan visi bersama, tujuan bersama, memahami insentif dan konsekuensi yang sesuai. Menunjukkan bahwa pendekatan semacam itu telah digunakan dan disebarluaskan.

12. Kemampuan Berhitung

Memiliki kemahiran interpretasi angka dalam proyek Lean Six Sigma Green Belt. Menjelaskan perlunya memiliki kecakapan dengan informasi numerik untuk melakukan proyek Lean Six Sigma Green Belt. Menunjukkan kemahiran menggunakan ukuran berdasarkan urutan besarnya pengaruh atau manfaat sebagai dasar dari semua ini agar mampu menghitung secara akurat berbagai perhitungan. Mengenali kapan waktu yang tepat untuk menggunakan komputer, dan dapat melakukannya secara efektif. Menunjukkan bahwa hasil yang dihitung masuk akal. Menunjukkan kemampuan interpolasi dan prediksi dari data dalam proyek Lean Six Sigma Green Belt, missal: grafik, diagram, bagan, dan tabel.

13. Kemampuan Solusi Masalah Praktek (Realisasi Kesempatan)

Memiliki kemampuan untuk membedakan berbagai jenis masalah / peluang dan memilih pendekatan yang tepat untuk mengatasinya. Misalnya, penyebab akut / kronis atau penyebab khusus / penyebab umum. Memahami bagaimana menerapkan teknik analisis akar penyebab masalah agar mengidentifikasi dan menghilangkan faktor-faktor penyebab itu untuk perbaikan proses. Memiliki kemampuan menggambarkan proses yang tepat digunakan untuk mengatasi berbagai jenis masalah. Menjelaskan di manahal ini sesuai. Menunjukkan penggunaan DMAIC (Define, Measure, Analyze, Improve, Control) yang tepat dan metode penyelesaian masalah lainnya, kualifikasi dari seleksi. Berpartisipasi dalam perbaikan proses setelah menemukan akar penyebab masalah utama itu. Menunjukkan keberhasilan penerapan berbagai teknik identifikasi dan pemilahan akar penyebab masalah praktis (misal. Diagram Mengapa-Mengapa, Bagan Pareto, Analisis Pohon Kesalahan, Diagram Sebab dan Akibat, dll). Memiliki kemampuan untuk mengedepankan solusi potensial dan memilih serta memverifikasi berdasarkan cara yang paling tepat. Menjelaskan proses pembuatan solusi masalah yang digunakan dan bagaimana proposal untuk mengatasi akar penyebab masalah yang diidentifikasi. Menjelaskan proses yang digunakan untuk menetapkan kriteria seleksi. Menjelaskan proses verifikasi untuk solusi masalah yang dipilih. Mendemonstrasikan penggunaan teknik yang tepat untuk menghasilkan solusi terhadap akar penyebab yang teridentifikasi apakah dihilangkan atau diminimumkan, kemudian mengurutkan, memilih dan memverifikasi hal-hal itu.

14. Kemampuan Presentasi dan Pelaporan

Memahami pentingnya berkomunikasi secara efektif. Menjelaskan cara yang efektif untuk menyusun presentasi dan laporan. Menunjukkan perencanaan dan penyampaian presentasi, formal atau informal, dan persiapan pembuatan laporan.

15. Kemampuan Keterampilan Pemikiran Proses

Memahami proses dan / atau sistem di mana proyek Lean Six Sigma Green Belt beroperasi dan dampak dari proyek tersebut. Memiliki kemampuan menggambarkan proses dan / atau sistem di mana proyek Lean Six Sigma Green Belt beroperasi dan dampak yang mungkin ditimbulkan dari proyek itu. Menunjukkan aplikasi alat proses / teknik yang sesuai seperti SIPOC (Supplier-Input-Process-Output-Customer), diagram alir, dll.

16. Kemampuan Manajemen Proyek

Memiliki kemampuan mengelola aktivitas peningkatan penggunaan waktu yang terbatas dengan sekelompok orang tertentu. Menjelaskan apa yang merupakan keterampilan manajemen proyek yang baik. Menunjukkan manajemen yang efektif dari proyek Lean Six Sigma Green Belt.

17. Kemampuan Analisis Risiko

Memiliki kemampuan memahami konsep risiko dalam proyek Lean Six Sigma Green Belt. Menjelaskan apa yang dimaksud dengan risiko dan bagaimana risiko itu dievaluasi dan diprioritaskan dalam proyek Lean Six Sigma Green Belt itu. Telah menunjukkan identifikasi risiko yang tepat serta menunjukkan bagaimana mengukur dan memprioritaskan penurunan atau penghilangan risiko itu. Memiliki kemampuan menggunakan alat manajemen risiko seperti: FMEA (Failure Mode and Effect Analysis) untuk menurunkan RPN (Risk Priority Number).

18. Kemampuan Peninjauan-ulang Mandiri dan Pengembangan

Memiliki kemampuan memahami kekuatan dan area yang membutuhkan pengembangan secara mandiri. Menggambarkan kekuatan dan rencana mandiri untuk pengembangan diri. Telah menunjukkan peninjauan-ulang mandiri (Self-review) dan tindakan yang sesuai telah diambil.

19. Kemampuan Menerapkan Alat-alat Lean Six Sigma

Memiliki kemampuan memahami penerapan alat dan teknik Lean Six Sigma. Menjelaskan penggunaan dan penerapan teknik-teknik itu. Telah mendemonstrasikan pemilihan dan penerapan dari alat dan teknik Lean Six Six Sigma yang tepat dalam proyek Lean Six Sigma Green Belt.

20. Kemampuan Manajemen Pemangku Kepentingan (Stakeholder Management)

Memiliki pengetahuan tentang manajemen pemangku kepentingan. Menjelaskan jenis pemangku kepentingan dan teknik yang tepat untuk manajemen pemangku kepentingan itu.

21. Kemampuan Memahami dan Menerapkan Konsep-konsep Statistika

Memiliki kemampuan memahami konsep dan metode statistika dan menggunakannya secara tepat. Menjelaskan penerapan konsep statistika yang tepat dalam proyek Lean Six Sigma Green Belt.

22. Kemampuan Menggunakan Software Statistika

Memiliki pengetahuan tentang aplikasi, kemampuan dan keterbatasan dari setidaknya satu alat perangkat lunak statistika, misalnya: Minitab, dan situasi saat yang tepat untuk menggunakan software itu. Menjelaskan penggunaan dan kekuatan dari satu paket perangkat lunak yang menjalankan analisis statistika, termasuk keterbatasan apa pun yang terdapat dalam software statistika itu. Menunjukkan kecakapan dalam setidaknya satu paket perangkat lunak statistika yang tersedia saat ini yang menjalankan analisis statistika, termasuk pengecekan yang masuk akal dan penyajian hasil analisis dalam proyek Lean Six Sigma Green Belt.

23. Kemampuan Keberlanjutan dan Pengendalian (Sustainability and Control)

Memiliki kemampuan memahami konsep kontrol atau pengendalian dalam proyek Lean Six Sigma Green Belt. Menjelaskan pentingnya keberlanjutan dari solusi yang diterapkan. Mendemonstrasikan langkah-langkah yang diambil untuk memastikan peningkatan kinerja proses itu dapat dipertahankan keberlanjutannya dari waktu ke waktu.

Secara umum dapat dikatakan bahwa terdapat 18 kompetensi inti berkaitan dengan Lean (Lean Practitioner, Lean Leader, Lean Expert) dan 23 kompetensi inti berkaitan dengan Six Sigma (Green Belt, Black Belt, Master Black Belt) yang dimaksudkan di dalam ISO 18404:2015, sebagai berikut:

18 Key competencies in Lean Management:

- Understanding benefits of lean

- Measurement of process performance

- Provide internal consultancy in Lean

- Creativity thinking

- Visual management

- Perform Lean audits

- Benchmarking

- Analysis of data

- Risk analysis

- Lean principles

- Motivating others

- Lean techniques

- Presentation skills

- Workplace Optimization

- Sustainability

- Use appropriate Lean tools

- Identification of suitable areas for Lean implementation

- Managing and training the competency

23 Key competencies in Six Sigma:

- Customer focus

- Decision making

- Motivating others

- Business process improvement

- Change management

- Leadership development (self and others)

- Creativity thinking

- Project management

- Statistical tools

- Presentation skills

- Organizational benefits identification and prioritization.

- Data acquisition for analysis

- Numeracy

- Six Sigma tools

- Statistical concepts and Software use

- Risk analysis

- Stakeholder Management

- Empowerment

- Process thinking skills

- Practical Problem Solving

- Sustainability and control

- Excellent Communication skills

- Training and mentoring Six sigma concepts and tools

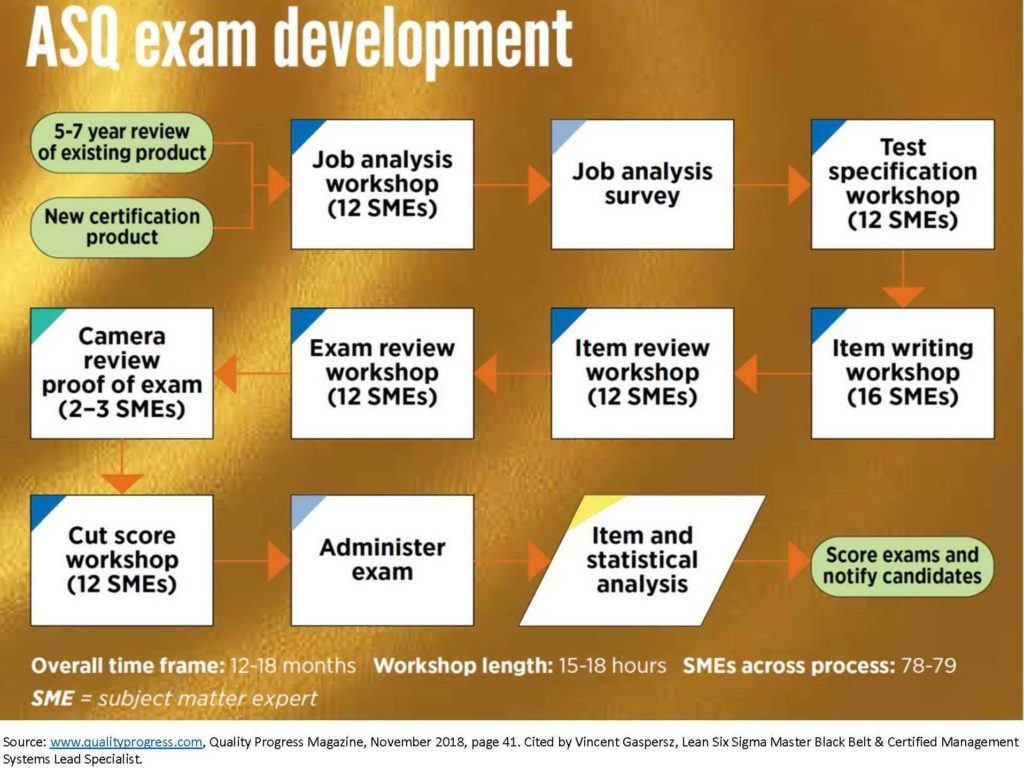

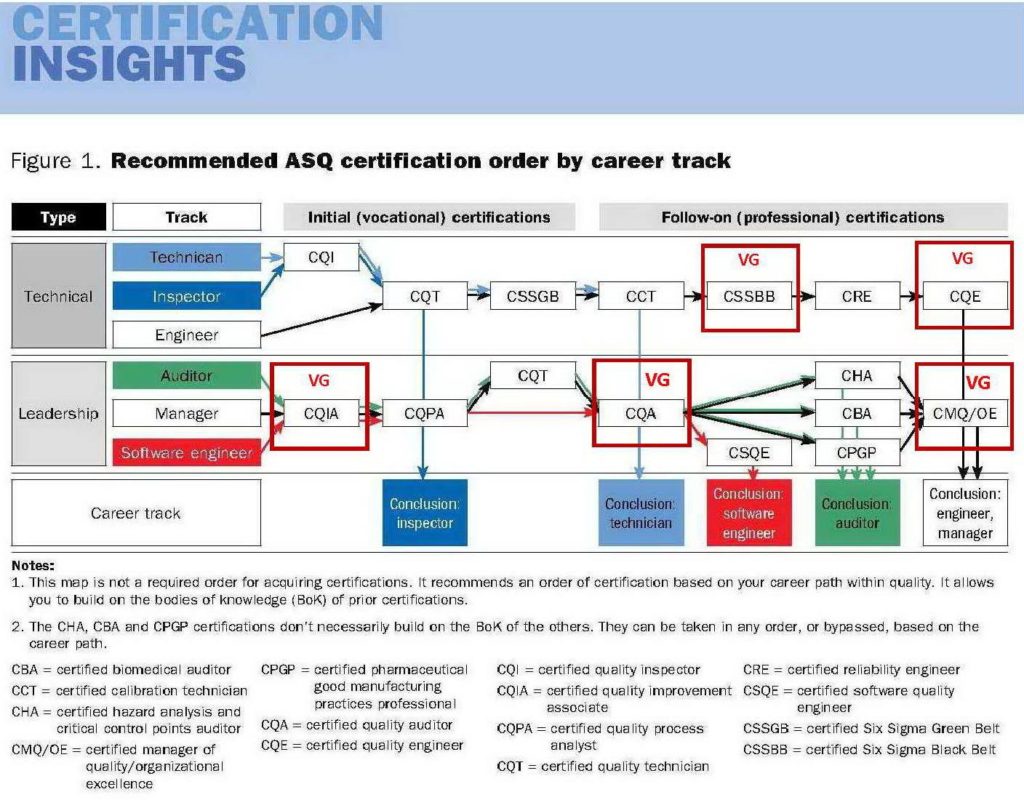

VG menawarkan kepada mereka yang memiliki GROWTH Mindset agar mempelajari termasuk menguji kompetensi mereka dalam bidang Lean Six Sigma, mulai dari yang paling rendah Yellow Belt sampai yang paling tinggi Master Black Belt, dengan urutan pembelajaran: (1) Yellow Belt, (2) Green Belt, (3) Black Belt, dan (4) Master Black Belt. Agar pengakuan kompetensi diakui secara internasional dan bergengsi, maka VG menyarankan mengikuti ujian internasional dari ASQ (American Society for Quality) dengan kurikulum ujian sebagai berikut. Kurikulum ujian tidak diterjemahkan ke dalam Bahasa Indonesia, agar memperoleh keasliannya.

Beberapa Jenis Sertifikasi Kompetensi Six Sigma dari ASQ:

Beberapa jenis sertifikasi kompetensi dari ASQ berkaitan dengan Six Sigma Green Belt dan Black Belt dapat dilihat dalam website: www.asq.org/cert. Sertifikasi kompetensi dari ASQ (CSSGB atau CSSBB) sangat bergengsi, karena didesain dan dikembangkan oleh para ahli dalam bidangnya termasuk para praktisi yang telah SUCCESS.

ASQ CSSYB (Certified Six Sigma Yellow Belt)

Source:

https://asq.org/cert/six-sigma-yellow-belt

Computer Delivered – the CSSYB examination is a one-part, 85-question, two-and-a-half-hour exam and is offered in English only. Seventy-five questions are scored and 10 are unscored.

Required Experience

The Six Sigma Yellow Belt (CSSYB) certification will be aimed at those new to the world of Six Sigma who have a small role, interest, or need to develop foundational knowledge. Yellow Belts can be entry-level employees who seek to improve their world or executive champions who require an overview of Six Sigma and DMAIC. This certification will adopt the approach of advancing the concept and potential of using Six Sigma tools and methodologies within an organization. The Six Sigma Yellow Belt certification requires no work experience.

Certified Six Sigma Yellow Belt (CSSYB) Body of Knowledge

Topics in this body of knowledge (BoK) include additional detail in the form of subtext explanations and the cognitive level at which test questions will be written. This information will provide guidance for the candidate preparing to take the exam. The subtext is not intended to limit the subject matter or be all-inclusive of what might be covered in an exam.

It is meant to clarify the type of content to be included in the exam. The descriptor in parentheses at the end of each entry refers to the maximum cognitive level at which the topic will be tested.

- Six Sigma Fundamentals (21 Questions)

A. Six Sigma Foundations and Principles

Describe the purpose of Six Sigma reducing variation), its methodology (DMAIC), and its evolution from quality. Describe the value of Six Sigma to the organization as a whole. (Understand).

B. Lean Foundations and Principles

Describe the purpose of lean (waste elimination) and its methodologies (just-in-time, poka-yoke, kanban, value stream mapping). Describe the value of lean to the organization as a whole. (Understand)

C. Six Sigma Roles and Responsibilities

Define and describe the roles and responsibilities of Six Sigma team members (i.e., individual team members, Yellow Belt, Green Belt, Black Belt, Master Black Belt, process owner, champion, sponsor). (Understand)

D. Team Basics

1. Types of teams

Identify the various types of teams that operate within an organization (i.e., continuous improvement, self-managed, and cross-functional) and their value. (Understand)

2. Stages of development

Describe the various stages of team evolution: forming, storming, norming, performing, and

adjourning. (Understand)

3. Decision-making tools

Define brainstorming, multivoting, and nominal group technique (NGT), and describe how these tools are used by teams. (Understand)

4. Communication methods

Explain how teams use agendas, meeting minutes, and project status reports, and how they support project success. (Understand)

E. Quality Tools and Six Sigma Metrics

1. Quality tools

Select and use these tools throughout the DMAIC process: Pareto charts, cause and effect diagrams, flowcharts, run charts, check sheets, scatter diagrams, and histograms. (Apply)

2. Six Sigma metrics

Select and use these metrics throughout the DMAIC process: defects per unit (DPU), defects per million opportunities (DPMO), rolled throughput yield (RTY), cycle time, and cost of poor quality (COPQ). (Apply)

II. Define Phase (12 Questions)

A. Project Identification

1. Voice of the customer

Define the voice of the customer and describe how customer needs are translated into quantifiable,

critical-to-quality (CTQ) characteristics. (Understand)

2. Project selection

Describe how projects are identified and selected as suitable for a Six Sigma project using the DMAIC methodology. (Understand)

3. Stakeholder analysis

Identify end users, subject matter experts, process owners, and other people or factors that will

be affected by a project, and describe how each of them can influence the project. (Understand)

4. Process inputs and outputs

Use SIPOC (suppliers, inputs, process, outputs, customers) to identify and define important elements of a process. (Apply)

B. Project Management (PM) Basics

1. Project charter

Describe the purpose of a charter and its components: problem statement, project scope, baseline data, and project goal. (Understand)

2. Communication plan

Explain the purpose and benefits of a communication plan and how it can impact the success of the project. (Understand)

3. Project planning

Define work breakdown structure (WBS) and Gantt charts, and describe how they are used to plan and monitor projects. (Understand)

4. Project management tools Select and use various PM tools: activity network diagrams, affinity diagrams, matrix charts, relations charts, and tree diagrams. (Understand)

5. Phase reviews

Explain how tollgate or phase reviews are used throughout the DMAIC life cycle. (Understand)

III. Measure Phase (15 Questions)

A. Basic Statistics

Define, calculate, and interpret measures of central tendency (mean, median, mode) and measures of dispersion (standard deviation, range, variance). (Apply)

B. Data Collection

1. Data collection plans

Describe the critical elements of a data collection plan, including an operational definition, data sources, the method to be used for gathering data, and how frequently it will be gathered. Describe why data collection plans are important. (Understand)

2. Qualitative and quantitative data

Define and distinguish between these types of data. (Understand)

3. Data collection techniques

Use various data collection techniques, including surveys, interviews, check sheets, and checklists to gather data that contributes to the process being improved. (Apply)

C. Measurement System Analysis (MSA)

- MSA terms

Define precision, accuracy, bias, linearity, and stability, and describe how these terms are applied in the measurement phase. (Understand)

2. Gauge repeatability and reproducibility (GR&R)

Describe how and why GR&R is used in the measurement phase. (Understand)

IV. Analyze Phase (15 Questions)

A. Process Analysis Tools

1. Lean tools

Define how 5S and value analysis can be used to identify and eliminate waste. (Understand)

2. Failure mode and effects analysis (FMEA)

Define the elements of severity, opportunity, and detection, and determine how they are used to calculate the risk priority number. .Describe how FMEA can be used to identify potential failures in a process. (Understand)

B. Root Cause Analysis

Describe how the 5 Whys, process mapping, force-field analysis, and matrix charts can be u used to identify the root causes of a problem. (Understand)

C. Data Analysis

1. Basic distribution types

Define and distinguish between normal and binomial distributions and describe how their shapes (skewed and bimodal) can affect data interpretation. (Understand)

2. Common and special cause variation

Describe and distinguish between these types of variation. (Understand)

D. Correlation and Regression

1. Correlation

Describe how correlation is used to identify relationships between variables. (Understand)

2. Regression

Describe how regression analysis is used to predict outcomes. (Understand)

E. Hypothesis Testing

Define and distinguish between hypothesis terms (i.e., null and alternative, type I and type II error, p-value and power). (Understand)

V. Improve and Control Phases (12 Questions)

A. Improvement Techniques

1. Kaizen and kaizen blitz

Define and distinguish between these two methods and describe how they can be used to make improvements to any process in an organization. (Understand)

2. Plan-do-check-act (PDCA) cycle

Define and distinguish between the steps in this process improvement tool. (Understand)

3. Cost-benefit analysis

Explain the importance of this analysis and how it is used in the improve phase. (Understand)

B. Control Tools and Documentation

1. Control plan

Describe the importance of a control plan for maintaining improvements. (Understand)

2. Control charts

Describe how X-R charts are used for monitoring and sustaining improved processes. (Understand)

3. Document control

Describe the importance of documenting changes to a process and communicating those changes to stakeholders. (Understand)

ASQ CSSGB (Certified Six Sigma Green Belt)

Source:

https://asq.org/cert/six-sigma-green-belt

REQUIREMENTS

Here are the requirements and exam specifics for a Certified Six Sigma Green Belt.

Work Experience

Six Sigma Green Belts are employees who spend some of their time on process improvement teams. They analyze and solve quality problems, and are involved with Six Sigma, lean or other quality improvement projects.

The Six Sigma Green Belt certification requires three years of work experience in one or more areas of the Six Sigma Green Belt Body of Knowledge.

Candidates must have worked in a full-time, paid role. Paid intern, co-op or any other course work cannot be applied toward the work experience requirement.

Education

Educational waivers are not granted.

Expectations

Here are the minimum expectations of a Certified Six Sigma Green Belt.

- Operates in support of or under the supervision of a Six Sigma Black Belt.

- Analyzes and solves quality problems.

- Involved in quality improvement projects.

- Participated in a project, but has not led a project.

- Has at least three years of work experience.

- Has ability to demonstrate their knowledge of Six Sigma tools and processes.

Certification from ASQ is considered a mark of quality excellence in many industries. It helps you advance your career and boosts your organization’s bottom line through your mastery of quality skills. Becoming certified as a Six Sigma Green Belt confirms your commitment to quality and the positive impact it will have on your organization.

Examination

Each certification candidate is required to pass a written examination that consists of multiple-choice questions that measure comprehension of the body of knowledge.

Certified Six Sigma Green Belt (CSSGB)

The Six Sigma Green Belt (CSSGB) operates in support or under the supervision of a Six Sigma Black Belt, analyzes and solves quality problems, and is involved in quality improvement projects. A Green Belt has at least three years of work experience and wants to demonstrate his or her knowledge of Six Sigma tools and processes.

CSSGB

Computer Delivered – the CSSGB examination is a one-part, 110-question, four-and-a-halfhour exam and is offered in English only. One hundred questions are scored and 10 are unscored.

Experience Required

Six Sigma Green Belts are employees who spend some of their time on process improvement teams. They analyze and solve quality problems, and are involved with Six Sigma, lean, or other quality improvement projects. The Six Sigma Green Belt certification requires three years of work experience in one or more areas of the Six Sigma Green Belt Body of Knowledge. Work experience must be in a full-time, paid role. Paid intern, co-op, or any other course work cannot be applied toward the work experience requirement. Educational waivers are not granted.

Certified Six Sigma Green Belt (CSSGB)

Topics included in this body of knowledge (BoK) are explanations (subtext) and cognitive levels for each topic or subtopic in the test. These details will be used by the Examination Development Committee as guidelines for writing test questions and are designed to help candidates prepare for the exam by identifying specific content within each topic that can be tested. Except where specified, the subtext is not intended to limit the subject or be all inclusive

of what might be covered in an exam but is intended to clarify how topics are related to the role of the Certified Six Sigma Green Belt (CSSGB). The descriptor in parentheses at the end of each subtext entry refers to the highest cognitive level at which the topic will be tested. A complete description of cognitive levels is provided at the end of this document.

BODY OF KNOWLEDGE

I. Overview: Six Sigma and the Organization (13 Questions)

A. Six Sigma and Organizational Goals

1. Value of Six Sigma

Recognize why organizations use Six Sigma, how they apply its philosophy and goals, and the

evolution of Six Sigma from quality leaders such as Juran, Deming, Shewhart, Ishikawa, and others. (Understand)

- Organizational goals and Six Sigma projects

Identify the linkages and supports that need to be established between a selected Six Sigma project and the organization’s goals, and describe how process inputs, outputs, and feedback at all levels can influence the organization as a whole. (Understand)

- Organizational drivers and metrics

Recognize key business drivers (profit, market share, customer satisfaction, efficiency, product

differentiation) for all types of organizations. Understand how key metrics and scorecards are

developed and how they impact the entire organization. (Understand)

B. Lean Principles in the Organization

1. Lean concepts

Define and describe lean concepts such as theory of constraints, value chain, flow, and perfection. (Apply)

2. Value stream mapping

Use value stream mapping to identify value-added processes and steps or processes that produce waste, including excess inventory, unused space, test inspection, rework, transportation, and storage. (Understand)

Topics included in this body of knowledge (BoK) are explanations (subtext) and cognitive levels for each topic or subtopic in the test. These details will be used by the Examination Development Committee as guidelines for writing test questions and are designed to help candidates prepare for the exam by identifying specific content within each topic that can be tested. Except where specified, the subtext is not intended to limit the subject or be all inclusive

of what might be covered in an exam but is intended to clarify how topics are related to the role of the Certified Six Sigma Green Belt (CSSGB). The descriptor in parentheses at the end of each subtext entry refers to the highest cognitive level at which the topic will be tested. A complete description of cognitive levels is provided at the end of this document.

C. Design for Six Sigma (DfSS) Methodologies

1. Road maps for DfSS

Distinguish between DMADV (define, measure, analyze, design, verify) and IDOV (identify, design, optimize, verify), and recognize how they align with DMAIC. Describe how these methodologies are used for improving the end product or process during the design (DfSS) phase. (Understand)

2. Basic failure mode and effects analysis (FMEA)

Use FMEA to evaluate a process or product and determine what might cause it to fail and the effects that failure could have. Identify and use scale criteria, calculate the risk priority number (RPN), and analyse the results. (Analyze)

3. Design FMEA and process FMEA

Define and distinguish between these two uses of FMEA. (Apply)

II. Define Phase (23 Questions)

A. Project Identification

1. Project selection

Describe the project selection process and what factors should be considered in deciding whether to use the Six Sigma DMAIC methodology or another problem solving

process. (Understand)

2. Process elements

Define and describe process components and boundaries. Recognize how processes cross various functional areas and the challenges that result for process improvement efforts. (Analyze)

3. Benchmarking

Understand various types of benchmarking, including competitive, collaborative, and best practices. (Understand)

4. Process inputs and outputs

Identify process input and output variables and evaluate their relationships using the supplier,

input, process, output, customer (SIPOC) model. (Analyze)

5. Owners and stakeholders

Identify the process owners and other stakeholders in a project. (Apply)

B. Voice of the Customer (VoC)

1. Customer identification

Identify the internal and external customers of a project, and what effect the project will have on them. (Apply)

2. Customer data

Collect feedback from customers using surveys, focus groups, interviews, and various forms of observation. Identify the key elements that make these tools effective. Review data collection questions to eliminate vagueness, ambiguity, and any unintendedbias. (Apply)

3. Customer requirements

Use quality function deployment (QFD) to translate customer requirements statements into product features, performance measures, or opportunities for improvement. Use weighting methods as needed to amplify the importance and urgency of different kinds of input; telephone call vs. survey response; product complaint vs. expedited service request. (Apply)

C. Project Management Basics

1. Project charter

Define and describe elements of a project charter and develop a problem statement that includes

baseline data or current status to be improved and the project’s goals. (Apply)

2. Project scope

Help define the scope of the project using process maps, Pareto charts, and other quality tools. (Apply)

3. Project metrics

Help develop primary metrics (reduce defect levels by x-amount) and consequential metrics (the negative effects that making the planned improvement might cause). (Apply)

4. Project planning tools

Use Gantt charts, critical path method (CPM), and program evaluation and review technique

(PERT) charts to plan projects and monitor their progress. (Apply)

5. Project documentation

Describe the types of data and input needed to document a project. Identify and help develop appropriate presentation tools (storyboards, spreadsheet summary of results) for phase reviews and management updates. (Apply)

6. Project risk analysis

Describe the elements of a project risk analysis, including feasibility, potential impact, and risk priority number (RPN). Identify the potential effect risk can have on project goals and schedule, resources (materials and personnel), costs and other financial measures, and stakeholders. (Understand)

7. Project closure

Review with team members and sponsors the project objectives achieved in relation to the charter and ensure that documentation is completed and stored appropriately. Identify lessons learned and inform other parts of the organization about opportunities for improvement. (Apply)

D. Management and Planning Tools

Define, select, and apply these tools: 1) affinity diagrams, 2) interrelationship digraphs, 3) tree diagrams, 4) prioritization matrices, 5) matrix diagrams, 6) process decision program charts (PDPC), and 7) activity network diagrams. (Apply)

E. Business Results for Projects

1. Process performance

Calculate process performance metrics such as defects per unit (DPU), rolled throughput yield

(RTY), cost of poor quality (CoPQ), defects per million opportunities (DPMO), sigma levels, and process capability indices. Track process performance measures to drive project decisions. (Analyze)

2. Communication

Define and describe communication techniques used in organizations: top-down, bottom-up, and horizontal. (Apply)

F. Team Dynamics and Performance

1. Team stages and dynamics

Define and describe the stages of team evolution, including forming, storming, norming, performing, adjourning, and recognition. Identify and help resolve negative dynamics such as overbearing, dominant, or reluctant participants, the unquestioned acceptance of opinions as facts, groupthink, feuding, floundering, the rush to accomplishment, attribution, discounts, digressions, and tangents. (Understand)

2. Team roles and responsibilities

Describe and define the roles and responsibilities of participants on Six Sigma and other teams, including Black Belt, Master Black Belt, Green Belt, champion, executive, coach, facilitator, team member, sponsor, and process owner. (Apply)

3. Team tools

Define and apply team tools such as brainstorming, nominal group technique, and multivoting. (Apply)

4. Team Communication

Identify and use appropriate communication methods (both within the team and from the team

to various stakeholders) to report progress, conduct reviews, and support the overall success of the project. (Apply)

III. Measure Phase (23 Questions)

A. Process Analysis and Documentation

Develop process maps and review written procedures, work instructions, and flowcharts to identify any gaps or areas of the process that are misaligned. (Create)

B. Probability and Statistics

1. Basic probability concepts

Identify and use basic probability concepts: independent events, mutually exclusive events, multiplication rules, permutations, and combinations. (Apply)

2. Central limit theorem

Define the central limit theorem and describe its significance in relation to confidence intervals,

hypothesis testing, and control charts. (Understand)

C. Statistical Distributions

Define and describe various distributions as they apply to statistical process control and probability: normal, binomial, Poisson, chi square, Student’s t, and F. (Understand)

D. Collecting and Summarizing Data

1. Types of data and measurement scales

Identify and classify continuous (variables) and discrete (attributes) data. Describe and define

nominal, ordinal, interval, and ratio measurement scales. (Analyze)

2. Sampling and data collection methods

Define and apply various sampling methods (random and stratified) and data collection methods (check sheets and data coding). (Apply)

3. Descriptive statistics

Define, calculate, and interpret measures of dispersion and central tendency. Develop and interpret frequency distributions and cumulative frequency distributions. (Evaluate)

4. Graphical methods

Construct and interpret diagrams and charts that are designed to communicate numerical analysis efficiently, including scatter diagrams, normal probability plots, histograms, stem-and-leaf plots, box-and-whisker plots. (Create)

E. Measurement System Analysis (MSA)

Calculate, analyze, and interpret measurement system capability using gauge repeatability and reproducibility (GR&R) studies, measurement correlation, bias, linearity, percent agreement, and precision/tolerance (P/T). (Evaluate)

F. Process and Performance Capability

1. Process performance vs. process specifications

Define and distinguish between natural process limits and specification limits, and calculate process performance metrics. (Evaluate)

2. Process capability studies

Define, describe, and conduct process capability studies, including identifying characteristics, specifications, and tolerances, and verifying stability and normality. (Evaluate)

3. Process capability (Cp, Cpk) and process performance (Pp, Ppk) indices

Describe the relationship between these types of indices. Define, select, and calculate process capability and process performance. Describe when Cpm measures can be used. Calculate the sigma level of a process. (Evaluate)

4. Short-term vs. long-term capability and sigma shift

Describe the assumptions and conventions that are appropriate to use when only short-term data are used. Identify and calculate the sigma shift that occurs when long- and short-term data are compared. (Evaluate)

IV. Analyze Phase (15 Questions)

A. Exploratory Data Analysis

- Multi-vari studies

Select appropriate sampling plans to create multi-vari study charts and interpret the results for positional, cyclical, and temporal variation. (Create)

2. Correlation and linear regression

Describe the difference between correlation and causation. Calculate the correlation coefficient and linear regression and interpret the results in terms of statistical significance (p-value). Use

regression models for estimation and prediction. (Evaluate)

B. Hypothesis Testing

1. Basics

Distinguish between statistical and practical significance. Determine appropriate sample sizes and develop tests for significance level, power, and type I and type II errors. (Apply)

2. Tests for means, variances, and proportions

Conduct hypothesis tests to compare means, variances, and proportions (paired-comparison t-test, F-test, analysis of variance [ANOVA], chi square) and interpret the results. (Analyze)

V. Improve Phase (15 Questions)

A. Design of Experiments (DoE)

1. Basic terms

Define and describe terms such as independent and dependent variables, factors and levels, responses, treatments, errors, repetition, blocks, randomization, effects, and replication. (Understand)

2. DoE graphs and plots

Interpret main effects analysis and interaction plots. (Apply)

B. Root Cause Analysis

Use cause and effect diagrams, relational matrices, and other problem solving tools to identify the true cause of a problem. (Analyze)

C. Lean Tools

1. Waste elimination

Select and apply tools and techniques for eliminating or preventing waste, including pull systems, kanban, 5S, standard work, and poka-yoke. (Apply)

2. Cycle-time reduction

Use various techniques to reduce cycle time (continuous flow, setup reduction). (Analyze)

3. Kaizen and kaizen blitz

Define and distinguish between these two methods and apply them in various situations. (Apply)

VI. Control Phase (11 Questions)

A. Statistical Process Control (SPC)

1. SPC Basics

Describe the theory and objectives of SPC, including measuring and monitoring process performance for both continuous and discrete data. Define and distinguish between common and special cause variation and how these conditions can be deduced from control chart analysis. (Analyze)

2. Rational subgrouping

Define and describe how rational subgrouping is used. (Understand)

3. Control charts

Identify, select, construct, and use control charts: X-R, X-s, individual and moving range (ImR or XmR), median, p, np, c, and u. (Apply)

B. Control Plan

Assist in developing and implementing a control plan to document and monitor the process and maintain the improvements. (Apply)

C. Lean Tools for Process Control

1. Total productive maintenance (TPM)

Define the elements of TPM and describe how it can be used to control the improved process.

(Understand)

2. Visual factory

Define the elements of a visual factory and describe how it can be used to control the improved

process. (Understand)

LEVELS OF COGNITION (Based on Bloom’s Taxonomy—Revised (2001)

In addition to content specifics, the subtext for each topic in this BoK also indicates the intended complexity level of the test questions for that topic. These levels are based on “Levels of Cognition” (from Bloom’s Taxonomy—Revised, 2001) and are presented below in rank order, from least complex to most complex..

REMEMBER | Recall or recognize terms, definitions, facts, ideas, materials, patterns, sequences, methods, principles, etc.

UNDERSTAND | Read and understand descriptions, communications, reports, tables, diagrams, directions, regulations, etc.

APPLY | Know when and how to use ideas, procedures, methods, formulas, principles, theories, etc.

ANALYZE | Break down information into its constituent parts and recognize their relationship to one another and how they are organized; identify sublevel factors or salient data from a complex scenario.

EVALUATE | Make judgments about the value of proposed ideas, solutions, etc., by comparing the proposal to specific criteria or standards.

CREATE | Put parts or elements together in such a way as to reveal a pattern or structure not clearly there before; identify which data or information from a complex set is appropriate to examine further or from which supported conclusions can be drawn.

Kurikulum ASQ CSSBB (Certified Six Sigma Black Belt)

Source:

https://asq.org/cert/six-sigma-black-belt

Kurikulum CSSBB telah bersifat lanjutan dengan persyaratan yang lebih ketat. Kurikulum ASQ CSSBB tidak diterjemahkan ke dalam Bahasa Indonesia agar dapat memahami keasliannya.

REQUIREMENTS

Here are the experience and exam specifics for the Certified Six Sigma Black Belt.

Work Experience

Six Sigma Black Belt requires two completed projects with signed affidavits or one completed project with signed affidavit and three years of work experience in one or more areas of the Six Sigma Body of Knowledge. For more information, please see the list of Six Sigma Project Affidavit FAQs. You do not need to be a Certified Six Sigma Green Belt.

Work experience must be in a full time, paid role. Paid intern, co-op or any other course work cannot be applied towards the work experience requirement.

Expectations

These are the minimum expectations of a Certified Six Sigma Black Belt.

I: Organization-wide Planning and Deployment

- Will understand how to deploy six sigma within a project.

- Will be able to implement tools and techniques to deploy strategic directions for initiatives.

- Will understand the roles and responsibilities for six sigma projects and how each group influences project deployment, and will be able to support communications about the project deployment.

- Will be able to apply operational change management techniques within their defined scope or domain.

II: Organizational Process Management and Measures

- Will be able to define various types of benchmarking.

- Will be able to describe various types of performance measures, and select an appropriate financial measure for a given situation and calculate its result.

III: Team Management

- Will understand the components and techniques used in managing teams, including time management, planning and decision-making tools, team formation, motivational techniques and factors that demotivate a team, performance evaluation and reward.

- Will be able to describe elements that can result in a team’s success.

- Will be able to use appropriate techniques to overcome various group dynamics challenges.

IV: Define

- Will be able to select data collection methods and collect voice of the customer data, and use customer feedback to determine customer requirements.

- Will understand the elements of a project charter (problem statement, scope, goals, etc.) and be able to use various tools to track the project progress.

V: Measure

- Will be able to define and use process flow metrics and analysis tools to indicate the performance of a process.

- Will be able to develop and implement data collection plans, and use techniques in sampling, data capture, and processing tools.

- Will be able to define and describe measurement system analysis tools.

- Will apply basic probability concepts, and understand various distributions.

- Will be able to calculate statistical and process capability indices.

VI: Analyze

- Will be able to analyze the results of correlation and regression analyses.

- Will be able to define multivariate tools.

- Will be able to perform hypothesis tests for means, variances and proportions and analyze their results.

- Will understand the components and concepts for ANOVA, Chi-square, contingency tables, and non-parametric tests.

- Will understand the elements and purpose of FMEA and use root cause analysis tools.

- Will be able to identify and interpret the 7 classic wastes.

- Will be able to use gap analysis tools.

VII: Improve

- Will be able to define and apply design of experiments (DOE) principles, and distinguish among the various types of experiments.

- Will be able to apply various lean tools and techniques to eliminate waste and reduce cycle time.

- Will understand how to implement an improved process and how to analyze and interpret risk studies.

VIII: Control

- Will be able to apply, use, and analyze the various statistical process control (SPC) techniques.

- Will understand total productive maintenance (TPM) and visual factory concepts.

- Will be able to develop control plans and use various tools to maintain and sustain improvements.

IX: Design For Six Sigma (DFSS) Framework and Methodologies

Certified Six Sigma Black Belt (CSSBB) Body of Knowledge

The Certified Six Sigma Black Belt (CSSBB) is a professional who can explain Six Sigma philosophies and principles, including supporting systems and tools. A Black Belt should demonstrate team leadership, understand team dynamics, and assign team member roles and responsibilities. Black Belts have a thorough understanding of all aspects of the DMAIC model in accordance with Six Sigma principles. They have basic knowledge of lean enterprise concepts, are able to identify nonvalue-added elements and activities, and are able to use specific tools.

CSSBB

Computer Delivered with the CSSBB examination is a one-part, 165-question, four-and-a-half-hour exam and is offered in English only. One hundred and fifty questions are scored and 15 are unscored.

Experience Required

Six Sigma Black Belt requires two completed projects with signed affidavits, or one completed project with a signed affidavit and three years of work experience, in one or more areas of the Six Sigma Black Belt Body of Knowledge.

I. Organization-Wide Planning and Deployment (12 Questions)

A. Organization-wide Considerations

1.

Fundamentals of Six Sigma and lean methodologies

Define and describe the value, foundations, philosophy, history, and goals of these approaches, and describe the integration and complementary relationship between them. (Understand)

- Six Sigma, lean, and

continuous improvement methodologies

Describe when to use Six Sigma instead of other problem-solving approaches, and describe the importance of aligning Six Sigma objectives with organizational goals. Describe screening criteria and how such criteria can be used for the selection of Six Sigma projects, lean initiatives, and other continuous improvement methods. (Apply)

- Relationships among

business systems and processes

Describe the interactive relationships among business systems, processes, and internal and external stakeholders, and the impact those relationships have on business systems. (Understand)

- Strategic planning

and deployment for initiatives

Define the importance of strategic planning for Six Sigma projects and lean initiatives. Demonstrate how hoshin kanri (X-matrix), portfolio analysis, and other tools can be used in support of strategic deployment of these projects. Use feasibility studies, SWOT analysis (strengths, weaknesses, opportunities, and threats), PEST analysis (political, economic, social, and technological) and contingency planning and business continuity planning to enhance strategic planning and deployment. (Apply)

B. Leadership

1. Roles and responsibilities

Describe the roles and responsibilities of executive leadership, champions,

sponsors, process owners, Master Black Belts, Black Belts, and Green Belts in

driving Six Sigma and lean initiatives. Describe how each group influences

project deployment in terms of providing or managing resources, enabling

changes in organizational structure, and supporting communications about the

purpose and deployment of the initiatives. (Understand)

2. Organizational roadblocks

and change management

Describe how an organization’s structure and culture can impact Six Sigma

projects. Identify common causes of Six Sigma failures, including lack of

management support and lack of resources. Apply change management techniques,

including stakeholder analysis, readiness assessments, and communication plans

to overcome barriers and drive organization-wide change. (Apply)

II. Organizational Process Management and Measures (10 Questions)

A. Impact on Stakeholders

Describe the impact Six Sigma projects can have on customers, suppliers, and

other stakeholders. (Understand)

B.

Benchmarking

Define and distinguish between various types of benchmarking, e.g., best

practices, competitive, collaborative, breakthrough. Select measures and

performance goals for projects resulting from benchmarking activities. (Apply)

C. Business Measures

1.

Performance measures

Define and describe balanced scorecard, key performance indicators (KPIs),

customer loyalty metrics, and leading and lagging indicators. Explain how to

create a line of sight from performance measures to organizational strategies.

(Analyze)

2.

Financial measures

Define and use revenue growth, market share, margin, net present value (NPV),

return on investment (ROI), and cost benefit analysis (CBA). Explain the

difference between hard cost measures (from profit and loss statements) and

soft cost benefits of cost avoidance and reduction. (Apply)

III. Team Management (18 Questions)

A. Team Formation

1.

Team types and constraints

Define and describe various teams, including virtual, crossfunctional, and

self-directed. Determine what team type will work best for a given a set of

constraints, e.g., geography, technology availability, staff schedules, time

zones. (Apply)

2.

Team roles and responsibilities

Define and describe various team roles and responsibilities for leader,

facilitator, coach, and individual member. (Understand)

3.

Team member selection criteria

Describe various factors that influence the selection of team members,

including the ability to influence, openness to change, required skill sets,

subject matter expertise, and availability. (Apply)

4.

Team success factors

Identify and describe the elements necessary for successful teams, e.g.,

management support, clear goals, ground rules, timelines. (Apply)

B. Team Facilitation

1.

Motivational techniques

Describe and apply techniques to motivate team members. Identify factors that

can demotivate team members and describe techniques to overcome them. (Apply)

2.

Team stages of development

Identify and describe the classic stages of team development: forming,

storming, norming,

performing, and adjourning. (Apply)

3.

Team communication

Describe and explain the elements of an effective communication plan, e.g.,

audience identification, message type, medium, frequency. (Apply)

4.

Team leadership models

Describe and select appropriate leadership approaches (e.g., direct, coach,

support, delegate) to ensure team success. (Apply)

C. Team Dynamics

1.

Group behaviors

Identify and use various conflict resolution techniques (e.g., coaching,

mentoring, intervention) to overcome negative group dynamics, including

dominant and reluctant participants, groupthink, rushing to finish, and

digressions. (Evaluate)

2.

Meeting management

Select and use various meeting management techniques, including using agendas,

starting on time, requiring pre-work by attendees, and ensuring that the right

people and resources are available. (Apply)

3.

Team decision-making methods

Define, select, and use various tools (e.g., consensus, nominal group

technique, multi-voting) for decision making. (Apply)

D. Team Training

1.

Needs assessment

Identify the steps involved to implement an effective training curriculum:

identify skills gaps, develop learning objectives, prepare a training plan, and

develop training materials. (Understand)

2.

Delivery

Describe various techniques used to deliver effective training, including adult

learning theory, soft skills, and modes of learning. (Understand)

3.

Evaluation

Describe various techniques to evaluate training, including evaluation

planning, feedback surveys, pre-training and posttraining testing. (Understand)

IV. Define (20 Questions)

A. Voice of the Customer

1.

Customer Identification

Identify and segment customers and show how a project will impact both internal

and external customers. (Apply)

2.

Customer data collection

Identify and select appropriate data collection methods (e.g., surveys, focus

groups, interviews, observations) to gather voice of the customer data. Ensure

the data collection methods used are reviewed for validity and

reliability.(Analyze)

3.

Customer requirements

Define, select, and apply appropriate tools to determine customer needs and

requirements, including critical-to-X (CTX when “X” can be quality, cost,

safety, etc.), CTQ tree, quality function deployment (QFD), supplier, input,

process, output, customer (SIPOC), and Kano model. (Analyze)

B. Business Case and Project Charter

1.

Business case

Describe business case justification used to support projects. (Understand)

2.

Problem statement

Develop a project problem statement and evaluate it in relation to baseline

performance and improvement goals. (Evaluate)

3.

Project scope

Develop and review project boundaries to ensure that the project has value to

the customer. (Analyze)

4.

Goals and objectives

Identify specific, measureable, actionable, relevant, and time bound (SMART)

goals and objectives on the basis of the project’s problem statement and scope.

(Analyze)

5.

Project performance measurements

Identify and evaluate performance measurements (e.g., cost, revenue, delivery,

schedule, customer satisfaction) that connect critical elements of the process

to key outputs. (Analyze)

6.

Project charter review

Explain the importance of having periodic project charter reviews with

stakeholders. (Understand)

C.

Project Management (PM) Tools

Identify and use the following PM tools to track projects and document their

progress. (Evaluate)

1.

Gantt charts

2. Toll-gate reviews

3. Work breakdown structure (WBS)

4. RACI model (responsible, accountable, consulted, and informed)

D.

Analytical Tools

Identify and use the following analytical tools throughout the DMAIC cycle.

(Apply)

1.

Affinity diagrams

2. Tree diagrams

3. Matrix diagrams

4. Prioritization matrices

5. Activity network diagrams

V. Measure (25 Questions)

A. Process Characteristics

1.

Process flow metrics

Identify and use process flow metrics (e.g., work in progress (WIP), work in

queue (WIQ), touch time, takt time, cycle time, throughput) to determine

constraints. Describe the impact that “hidden factories” can have on process

flow metrics. (Analyze)

2.

Process analysis tools

Select, use, and evaluate various tools, e.g., value stream maps, process maps,

work instructions, flowcharts, spaghetti diagrams, circle diagrams, gemba walk.

(Evaluate)

B. Data Collection

1.

Types of data

Define, classify, and distinguish between qualitative and quantitative data,

and continuous and discrete data. (Evaluate)

2.

Measurement scales

Define and use nominal, ordinal, interval, and ratio measurement scales.

(Apply)

3.

Sampling

Define and describe sampling concepts, including representative selection,

homogeneity, bias, accuracy, and precision. Determine the appropriate sampling

method (e.g., random, stratified, systematic, subgroup, block) to obtain valid

representation in various situations. (Evaluate)

4.

Data collection plans and methods

Develop and implement data collection plans that include data capture and

processing tools, e.g., check sheets, data coding, data cleaning (imputation

techniques). Avoid data collection pitfalls by defining the metrics to be used

or collected, ensuring that collectors are trained in the tools and understand

how the data will be used, and checking for seasonality effects. (Analyze)

C. Measurement Systems

1.

Measurement system analysis (MSA)

Use gauge repeatability and reproducibility (R&R) studies and other MSA

tools (e.g., bias, correlation, linearity, precision to tolerance, percent

agreement) to analyze measurement system capability. (Evaluate)

2.

Measurement systems across the organization

Identify how measurement systems can be applied to marketing, sales,

engineering, research and development (R&D), supply chain management, and

customer satisfaction data. (Understand)

3.

Metrology

Define and describe elements of metrology, including calibration systems,

traceability to reference standards, and the control and integrity of

measurement devices and standards. (Understand)

D. Basic Statistics

1.

Basic statistical terms

Define and distinguish between population parameters and sample statistics,

e.g., proportion, mean, standard deviation. (Apply)

2.

Central limit theorem

Explain the central limit theorem and its significance in the application of

inferential statistics for confidence intervals, hypothesis tests, and control

charts. (Understand)

3.

Descriptive statistics

Calculate and interpret measures of dispersion and central tendency. (Evaluate)

4.

Graphical methods

Construct and interpret diagrams and charts, e.g., box-and-whisker plots,

scatter diagrams, histograms, normal probability plots, frequency distributions,

cumulative frequency distributions. (Evaluate)

5.

Valid statistical conclusions

Distinguish between descriptive and inferential statistical studies. Evaluate

how the results of statistical studies are used to draw valid conclusions.

(Evaluate)

E. Probability

1.

Basic concepts

Describe and apply probability concepts, e.g., independence, mutually exclusive

events, addition and multiplication rules, conditional probability,

complementary probability, joint occurrence of events. (Apply)

2.

Distributions

Describe, interpret, and use various distributions, e.g., normal, Poisson,

binomial, chi square, Student’s t, F, hypergeometric, bivariate, exponential,

lognormal, Weibull. (Evaluate)

F. Process Capability

1.

Process capability indices

Define, select, and calculate Cp and Cpk. (Evaluate)

2.

Process performance indices

Define, select, and calculate Pp, Ppk, Cpm, and process sigma. (Evaluate)

3.

General process capability studies

Describe and apply elements of designing and conducting process capability studies

relative to characteristics, specifications, sampling plans, stability, and

normality. (Evaluate)

4.

Process capability for attributes data

Calculate the process capability and process sigma level for attributes data.

(Apply)

5.

Process capability for non-normal data

Identify non-normal data and determine when it is appropriate to use Box-Cox or

other transformation techniques. (Apply)

6.

Process performance vs. specification

Distinguish between natural process limits and specification limits. Calculate

process performance metrics, e.g., percent defective, parts per million (PPM),

defects per million opportunities (DPMO), defects per unit (DPU), throughput

yield, rolled throughput yield (RTY). (Evaluate)

7.

Short-term and long-term capability

Describe and use appropriate assumptions and conventions when only short-term

data or only longterm data are available. Interpret the relationship between short-term

and long-term capability. (Evaluate)

VI. Analyze (22 Questions)

A. Measuring and Modeling Relationships Between Variables

1.

Correlation coefficient

Calculate and interpret the correlation coefficient and its confidence

interval, and describe the difference between correlation and causation.

(Evaluate)

2.

Linear regression

Calculate and interpret regression analysis, and apply and interpret hypothesis

tests for regression statistics. Use the regression model for estimation and

prediction, analyze the uncertainty in the estimate, and perform a residuals

analysis to validate the model. (Evaluate)

3.

Multivariate tools

Use and interpret multivariate tools (e.g., factor analysis, discriminant

analysis, multiple analysis of variance (MANOVA)) to investigate sources of

variation. (Evaluate)

B. Hypothesis Testing

1.

Terminology

Define and interpret the significance level, power, type I, and type II errors

of statistical tests. (Evaluate)

2.

Statistical vs. practical significance

Define, compare, and interpret statistical and practical significance.

(Evaluate)

3.

Sample size

Calculate sample size for common hypothesis tests: equality of means and

equality of proportions. (Apply)

4.

Point and interval estimates

Define and distinguish between confidence and prediction intervals. Define and

interpret the efficiency and bias of estimators. Calculate tolerance and

confidence intervals. (Evaluate)

5.

Tests for means, variances, and proportions

Use and interpret the results of hypothesis tests for means, variances, and

proportions. (Evaluate)

6.

Analysis of variance (ANOVA)

Select, calculate, and interpret the results of ANOVAs. (Evaluate)

7.

Goodness-of-fit (chi square) tests

Define, select, and interpret the results of these tests. (Evaluate)

8.

Contingency tables

Select, develop, and use contingency tables to determine statistical

significance. (Evaluate)

9.

Nonparametric tests

Understand the importance of the Kruskal-Wallis and Mann-Whitney tests and when

they should be used. (Understand)

C.

Failure Mode and Effects Analysis (FMEA)

Describe the purpose and elements of FMEA, including risk priority number

(RPN), and evaluate FMEA results for processes, products, and services.

Distinguish between design FMEA (DFMEA) and process FMEA (PFMEA), and interpret

their results. (Evaluate)

D. Additional Analysis Methods

1.

Gap analysis

Analyze scenarios to identify performance gaps, and compare current and future

states using predefined metrics. (Analyze)

2.

Root cause analysis

Define and describe the purpose of root cause analysis, recognize the issues

involved in identifying a root cause, and use various tools (e.g., 5 whys,

Pareto charts, fault tree analysis, cause and effect diagrams) to resolve

chronic problems. (Analyze)

3.

Waste analysis

Identify and interpret the seven classic wastes (overproduction, inventory,

defects, over-processing, waiting, motion, transportation) and resource

under-utilization. (Analyze)

VII. Improve (21 Questions)

A. Design of Experiments (DOE)

1.

Terminology

Define basic DOE terms, e.g., independent and dependent variables, factors and

levels, response, treatment, error, nested. (Understand)

2.

Design principles

Define and apply DOE principles, e.g., power, sample size, balance, repetition,

replication, order, efficiency, randomization, blocking, interaction,

confounding, resolution. (Apply)

3.

Planning experiments

Plan and evaluate DOEs by determining the objective, selecting appropriate

factors, responses, and measurement methods, and choosing the appropriate

design. (Evaluate)

4.

One-factor experiments

Design and conduct completely randomized, randomized block, and Latin square

designs, and evaluate their results. (Evaluate)

5.

Two-level fractional factorial experiments

Design, analyze, and interpret these types of experiments, and describe how

confounding can affect their use. (Evaluate)

6.

Full factorial experiments

Design, conduct, and analyze these types of experiments. (Evaluate)

B. Lean Methods

1.

Waste elimination

Select and apply tools and techniques for eliminating or preventing waste,

e.g., pull systems, kanban, 5S, standard work, poka-yoke. (Analyze)

2.

Cycle-time reduction

Use various tools and techniques for reducing cycle time, e.g., continuous

flow, single-minute exchange of die (SMED), heijunka (production leveling).

(Analyze)

3.

Kaizen

Define and distinguish between kaizen and kaizen blitz and describe when to use

each method. (Apply)

4.

Other improvement tools and techniques

Identify and describe how other process improvement methodologies are used,

e.g., theory of constraints (TOC), overall equipment effectiveness (OEE).

(Understand)

C.

Implementation

Develop plans for implementing proposed improvements, including conducting

pilot tests or simulations, and evaluate results to select the optimum

solution. (Evaluate)

VIII. Control (15 Questions)

A. Statistical Process Control (SPC)

1.

Objectives

Explain the objectives of SPC, including monitoring and controlling process

performance, tracking trends, runs, and reducing variation within a process.

(Understand)

2.

Selection of variables

Identify and select critical process characteristics for control chart

monitoring. (Apply)

3.

Rational subgrouping

Define and apply the principle of rational subgrouping. (Apply)

4.

Control chart selection

Select and use control charts in various situations: X-R, X-s, individual and

moving range (ImR), p, np, c, u, short-run SPC, and moving average. (Apply)

5.

Control chart analysis

Interpret control charts and distinguish between common and special causes

using rules for determining statistical control. (Analyze)

B. Other Controls

1.

Total productive maintenance (TPM)

Define the elements of TPM and describe how it can be used to consistently

control the improved process. (Understand)

2.

Visual controls

Define the elements of visual controls (e.g., pictures of correct procedures,

color-coded components, indicator lights), and describe how they can help

control the improved process. (Understand)

C. Maintain Controls

1.

Measurement system reanalysis

Review and evaluate measurement system capability as process capability

improves, and ensure that measurement capability is sufficient for its intended

use. (Evaluate)

2.

Control plan

Develop a control plan to maintain the improved process performance, enable

continuous improvement, and transfer responsibility from the project team to

the process owner. (Apply)

D. Sustain Improvements

1.

Lessons learned

Document the lessons learned from all phases of a project and identify how

improvements can be replicated and applied to other processes in the

organization. (Apply)

2.

Documentation

Develop or modify documents including standard operating procedures (SOPs),

work instructions, and control plans to ensure that the improvements are

sustained over time. (Apply)

3.

Training for process owners and staff

Develop and implement training plans to ensure consistent execution of revised

process methods and standards to maintain process improvements. (Apply)

4.

Ongoing evaluation

Identify and apply tools (e.g., control charts, control plans) for ongoing