-

Bahasa Indonesia

-

English

Oleh: Vincent Gaspersz, Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- APICS (www.apics.org) Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- International Quality Federation (www.iqf.org) Six Sigma Master Black Belt (SSMBB);

- ASQ (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Six Sigma Black Belt (CSSBB), Certified Quality Improvement Associate (CQIA);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Lead Specialist (CMSLS).

- Senior Member of American Society for Quality (Member #: 00749775), International Member of American Production and Inventory Control Society (Member #: 1023620), and Senior Member of Institute of Industrial and Systems Engineers (Member #: 880194630).

Pada dasarnya semua program studi Industrial Systems Engineering (Rekayasa Sistem Industri) di manapun berada dapat menyusun isi kurikulum berdasarkan standar internasional untuk meningkatkan daya saing lulusan program studi itu. Standar-standar internasional dapat berasal dari Institute of Industrial & Systems Engineers (IISE), ISO (International Organization for Standardization), atau kombinasi berbagai standar internasional, dll.

Tulisan berikut akan membahas tentang cara mendesain silabus mata kuliah Introduction to Industrial Systems Engineering (Pengantar Rekayasa Sistem Industri) berdasarkan kerangka kerja ISO/IEC/IEEE 15288:2015 tentang Systems and Softwares Engineering: Systems Life Cycle Processes.

ISO (the International Organization for Standardization) telah bekerjasama dengan IEC (the International Electrotechnical Commission), dan IEEE (The Institute of Electrical and Electronics Engineers) yang pada tahun 2015 telah mengeluarkan ISO/IEC/IEEE 15288:2015(E) tentang Systems and Softwares Engineering: Systems Life Cycle Processes.

ISO / IEC / IEEE 15288: 2015 menetapkan kerangka kerja umum tentang deskripsi proses untuk menggambarkan siklus hidup sistem yang diciptakan oleh manusia. Ini mendefinisikan serangkaian proses dan terminologi yang terkait dari sudut pandang teknik atau rekayasa (engineering). Proses ini dapat diterapkan pada tingkat manapun dalam hierarki struktur sistem. Sekumpulan item yang terpilih dari proses ini dapat diterapkan sepanjang siklus hidup untuk mengelola dan melakukan tahapan siklus hidup sistem (system’s life cycle). Hal ini dicapai melalui keterlibatan semua pemangku kepentingan (stakeholders), dengan tujuan akhir untuk mencapai kepuasan pelanggan.

ISO / IEC / IEEE 15288: 2015 juga memberikan proses yang mendukung definisi, pengendalian dan peningkatan proses siklus hidup sistem yang digunakan dalam semua organisasi atau proyek. Semua organisasi dan proyek (apa saja) dapat menggunakan proses ini saat mengakuisisi dan memasok sistem.

ISO / IEC / IEEE 15288: 2015 membahas sistem yang dibuat manusia dan dapat dikonfigurasi dengan satu atau lebih dari elemen sistem berikut: perangkat keras, perangkat lunak, data, manusia, proses (misalnya: proses pemberian layanan kepada pengguna), prosedur (misalnya, instruksi untuk operator), fasilitas, bahan dan entitas yang terjadi secara alamiah.

Kerangka Kerja ISO/IEC/IEEE 15288:2015(E)

Isi dari ISO/IEC/IEEE 15288:2015– Systems and Softwares Engineering: Systems Life Cycle Processes adalah sebagai berikut:

Introduction

- Overview

- Scope

- Purpose

- Field of Application

- Limitations

- Conformance

- Intended usage

- Full conformance

- Full conformance to outcomes

- Full conformance to tasks

- Tailored conformance

- Normative references

- Terms, definitions, and abbreviated terms

- Terms and definitions

- Abbreviated terms

- Key concepts and application of this International Standard

- Introduction

- System concepts

- Systems

- System structure

- Enabling systems

- Organization and project concepts

- Organizations

- Organization and project-level adoption

- Life cycle concepts

- System life cycle model

- System life cycle stages

- Process concepts

- Criteria for processes

- Description of processes

- General characteristics of processes

- Tailoring

- Processes in this standard

- Introduction

- Agreement processes

- Organizational project-enabling processes

- Technical management processes

- Technical processes

- Process application

- Process reference model

- System life cycle processes

- Agreement processes

- Acquisition process

- Supply process

- Organizational project-enabling processes

- Life cycle model management process

- Infrastructure management process

- Portfolio management process

- Human resource management process

- Quality management process

- Knowledge management process

- Technical management processes

- Project Planning Process

- Project assessment and control process

- Decision management process

- Risk management process

- Configuration management process

- Information management process

- Measurement process

- Quality assurance process

- Technical processes

- Business or mission analysis process

- Stakeholder needs and requirements definition process

- System requirements definition process

- Architecture definition process

- Design definition process

- System analysis process

- Implementation process

- Integration process

- Verification process

- Transition process

- Validation process

- Operation process

- Maintenance process

- Disposal process

- Agreement processes

- Annex A (normative): Tailoring Process

- Introduction

- Tailoring process

- Purpose

- Outcomes

- Activities and tasks

- Annex B (informative): Example process information items

- Introduction

- Annex C (informative): Process reference model for assessment purposes

- Introduction

- Conformance with ISO/IEC 15504-2

- General

- Requirements for process reference models

- Process descriptions

- The process reference model

- Annex D (informative): Process integration and process constructs

- Introduction

- Process constructs and their usage

- Annex E (informative) Process views

- Introduction

- The process view concept

- Process viewpoint

- Process view for specialty engineering

- Process view for interface management

- Annex F (Informative): Architecture modeling

- Introduction

- Viewpoints, views and model kinds used in architecture

- Logical and physical models

- Functional model

- Behavioural model

- Temporal model

- Structural model

- Mass model

- Layout model

- Network model

- Other model considerations

- Annex G (Informative) Application of system life cycle processes to a system of systems

Contoh Penyusunan Silabus Mata Kuliah Introduction to Industrial Systems Engineering (Pengantar Rekayasa Sistem Industri) Berbasis ISO/IEC/IEEE 15288:2015(E)

No Kode Mata Kuliah—XYZ 1234 – Introduction to Industrial Systems Engineering (Pengantar Rekayasa Sistem Industri)

Silabus:

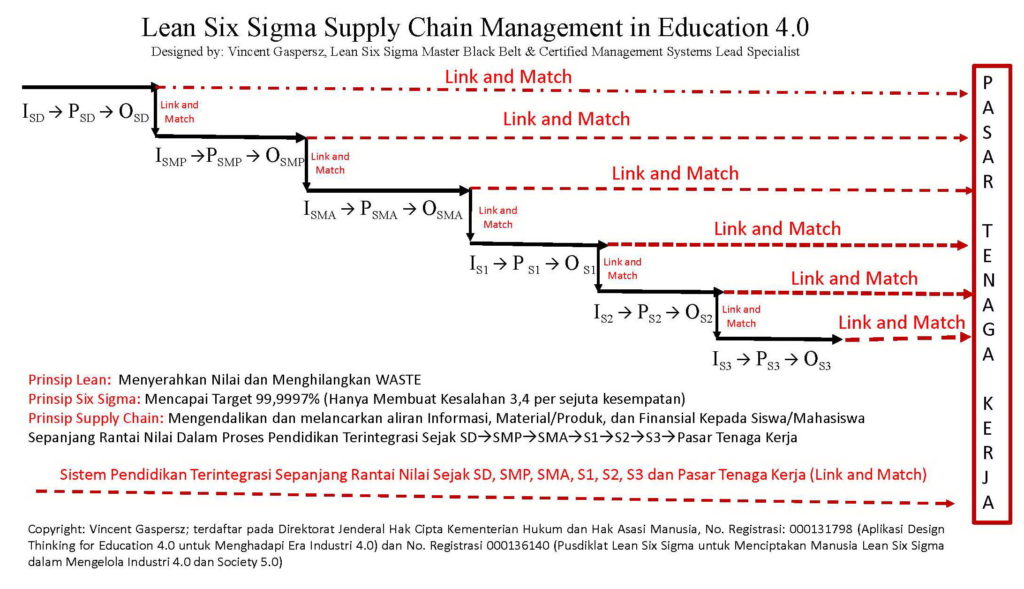

Produk, layanan dan proses dirancang dan dikembangkan dalam sistem industri yang semakin kompleks. Oleh karena itu, pemikiran sistem penting dalam produksi modern. Mata kuliah ini menyajikan kerangka kerja berdasarkan proses rekayasa sistem yang akan digunakan untuk perencanaan, analisis, dan perancangan sistem industri, seperti produk, pabrik manufaktur, proses operasional, sistem informasi, dan rantai pasokan. Pengenalan utama tahap-tahap sistem beserta life cycle akan diberikan, dengan fokus utama pada perancangan sistem, mulai dari desain konseptual hingga produksi. Topik utama dalam mata kuliah ini disusun mengacu kepada ISO/IEC/IEEE 15288:2015(E) sebagai berikut:

- System concepts

- Organization and project concepts

- Life cycle concepts

- Process concepts

- Process application

- Process reference model

System life cycle processes:

- Agreement processes

- Acquisition process

- Supply process

- Organizational project-enabling processes

- Life cycle model management process

- Infrastructure management process

- Portfolio management process

- Human resource management process

- Quality management process

- Knowledge management process

- Technical management processes

- Project Planning Process

- Project assessment and control process

- Decision management process

- Risk management process

- Configuration management process

- Information management process

- Measurement process

- Quality assurance process

- Technical processes

- Business or mission analysis process

- Stakeholder needs and requirements definition process

- System requirements definition process

- Architecture definition process

- Design definition process

- System analysis process

- Implementation process

- Integration process

- Verification process

- Transition process

- Validation process

- Operation process

- Maintenance process

- Disposal process

Lebih lanjut, Metode Analisis (Analytical Methods), Model-model Referensi (Reference Models), dan Indikator Kinerja Kunci (Key Performance Indicators) pada setiap tahap sistem dibahas.

Catatan: Semua metode analisis kuantitatif diintegrasikan langsung ke dalam pembahasan tahap-tahap sepanjang siklus hidup sistem (system’s life cycle).

Hasil Pembelajaran (Learning Outcome):

Mata kuliah ini mencakup pemahaman tentang keberlanjutan (sustainability) dan bagaimana aspek lingkungan dapat diintegrasikan ke dalam perancangan sistem.

Pengetahuan (Knowledge):

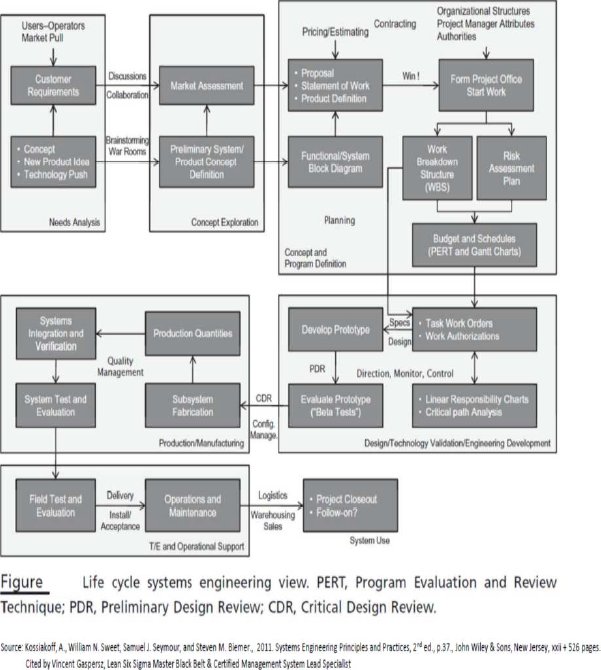

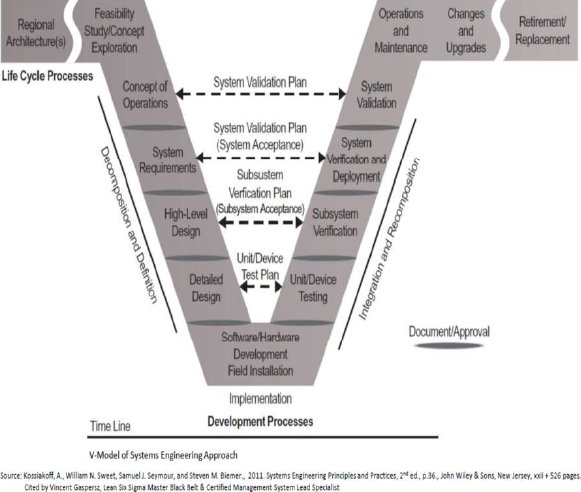

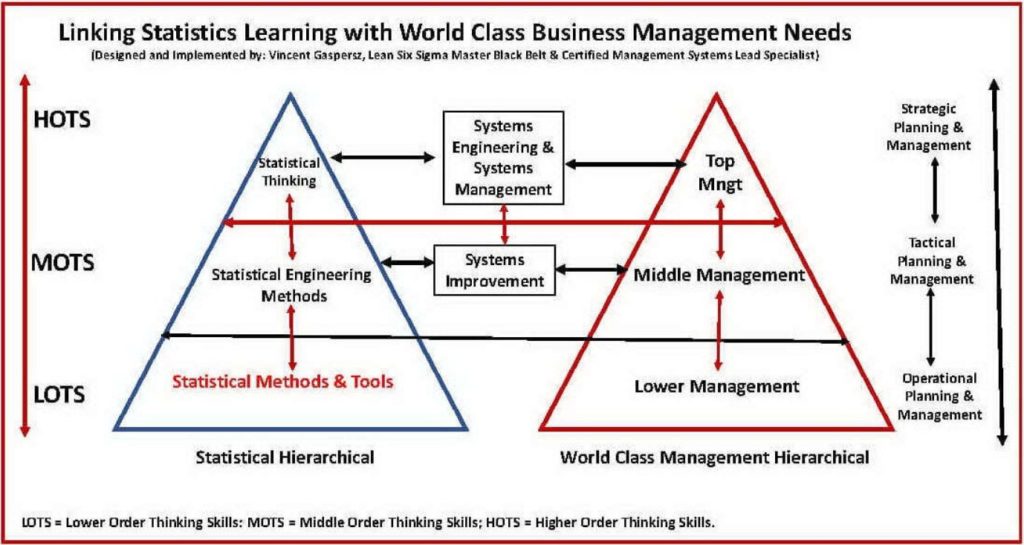

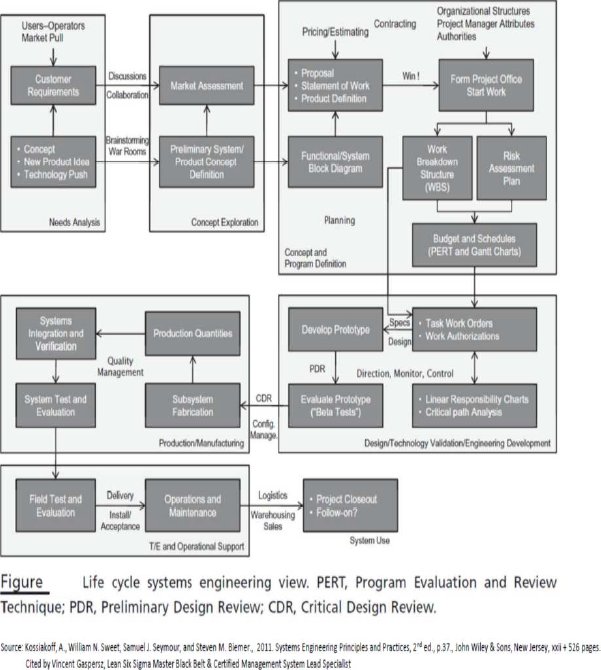

Pada akhir mengikuti mata kuliah ini, mahasiswa akan (1) MAMPU menjelaskan hubungan antara pemikiran sistem (Systems Thinking) dan rekayasa sistem (Systems Engineering); (2) MAMPU menjelaskan bagaimana V-model (lihat bagan terlampir) menyediakan peta jalan untuk praktek rekayasa sistem; (3) MAMPU menerapkan praktek rekayasa sistem ke sebuah proyek; dan (4) mengevaluasi sebuah proyek berdasarkan kualitas dari prosesnya.

Keterampilan (Skills):

Pada akhir mengikuti mata kuliah ini, mahasiswa siswa akan MAMPU (1) mengidentifikasi dan mempraktekkan kebiasaan berpikir sistem; (2) mengidentifikasi dan mendokumentasikan elemen-elemen sistem beserta interaksi dan keterkaitan antar-elemen sistem; (3) merancang tata letak (layout) pabrik atau proses produksi; dan, (4) menilai secara kritis tentang kualitas rekayasa sebuah sistem.

Kompetensi Umum (Attitude):

Pada akhir mengikuti mata kuliah ini, mahasiswa akan dapat (1) menerapkan pengetahuan tentang rekayasa sistem industri dalam sebuah proyek yang membutuhkan kerja tim multidisiplin dan multikultural; (2) melacak kemajuan, risiko dan aktivitas mitigasi risiko yang sedang berlangsung; dan, (3) mengkomunikasikan dan menjelaskan kontribusi rekayasa sistem terhadap pengembangan sistem.

Jika semua mata kuliah dari Pendidikan Tinggi di Indonesia disusun secara terintegrasi untuk membentuk standar KOMPETENSI MINIMUM dalam area pengetahuan tertentu, serta silabusnya mengikuti standar internasional, maka lulusan Pendidikan Tinggi di Indonesia akan MAMPU berkompetisi di pasar global (nasional, regional dan internasional). Dalam hal ini misalnya lulusan Teknik Sistem Industri (Industrial Systems Engineering) dari institusi Pendidikan di Papua, NTT, Kalimantan, Jawa, Sumatera, dll akan memiliki KOMPETENSI MINIMUM yang sama dengan lulusan dari disiplin ilmu teknik sistem industri dari Malaysia, Singapore, Australia, Canada, USA, dll karena semua pendidikan tinggi itu telah mengacu kepada standar internasional. Pada saat ini terjadi baru berlaku ungkapan Glocalitas (Think Globally Act Locally). Jika tidak maka ungkapan masyarakat cosmopolitan tentang standardisasi yaitu: “Berpikir Global, Bertindak Lokal” akan diinterpretasikan sesuka hati dan malahan bisa menjadi lebih buruk menjadi “Berpikir Lokal Bertindak Kampungan”.

Daftar Referensi:

- Badiru, A. B., 2014. Handbook of Industrial and Systems Engineering, 2nd ed., CRC Press, Florida., xiii+1.271 pages

- Garvey, P. R., 2009., Analytical Methods for Risk Management: A Systems

Engineering Perspective., CRC Press, New York, xviii + 264 pages. - ISO/IEC/IEEE 15288:2015(E). Systems and Sopftware Engineering—System Life Cycle Processes., ISO., Switzerland.

- Kossiakoff, A., William N. Sweet, Samuel J. Seymour, and Steven M. Biemer., 2011. Systems Engineering Principles and Practices, 2nd ed., John Wiley & Sons, New Jersey, xxii + 526 pages.

Understanding How to Design Industrial Systems Engineering Course Syllabus

By: Vincent Gaspersz, Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- APICS (www.apics.org) Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- International Quality Federation (www.iqf.org) Six Sigma Master Black Belt (SSMBB);

- ASQ (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Six Sigma Black Belt (CSSBB), Certified Quality Improvement Associate (CQIA);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Lead Specialist (CMSLS).

- Senior Member of American Society for Quality (Member #: 00749775), International Member of American Production and Inventory Control Society (Member #: 1023620), and Senior Member of Institute of Industrial and Systems Engineers (Member #: 880194630).

Basically, all Industrial Systems Engineering study programs, wherever they might be, can set their curriculum content based on international standards in order to improve the competitiveness of those study programs. The international standards can come from the Institute of Industrial & Systems Engineers (IISE), ISO (International Organization for Standardization), or a combination of various international standards, etc.

The following post will discuss how to design the course syllabus of Introduction to Industrial Systems Engineering based on ISO/IEC/IEEE 15288: 2015 framework on Systems and Softwares Engineering: Systems Life Cycle Processes.

ISO (the International Organization for Standardization), had collaborated with IEC (International Electrotechnical Commission) and IEEE (The Institute of Electrical and Electronics Engineers), issued ISO/IEC/IEEE 15288:2015(E) on Systems and Softwares Engineering: Systems Life Cycle Processes in 2015.

ISO/IEC/IEEE 15288:2015 establishes general framework of process descriptions to describe the life cycle of system created by people. It defines a set of related processes and terminology from the technical or engineering point of view. This process can be applied at any level in the hierarchy of the system structure. A set of selected items from this process can be applied throughout the life cycle to manage and perform system’s life cycle stages. This is achieved through the involvement of all stakeholders, with the ultimate goal of achieving customer satisfaction.

ISO/IEC/IEEE 15288:2015 also provides process that supports the definition, control and improvement of system’s life cycle process that are used in all organizations or projects. All organizations and projects (anything) can use this process when acquiring and supplying systems.

ISO/IEC/IEEE 15288:2015 discusses man-made systems and can be configured with one or more of the following system elements: hardware, software, data, human, process (e.g. service delivery process to users), procedure (e.g. instruction for an operator), facility, material and entity that occur naturally.

ISO/IEC/IEEE 15288:2015(E) Framework

The contents of ISO/IEC/IEEE 15288:2015 – Systems and Softwares Engineering: Systems Life Cycle Processes are as follows:

Introduction

- Overview

- Scope

- Purpose

- Field of Application

- Limitations

- Conformance

- Intended usage

- Full conformance

- Full conformance to outcomes

- Full conformance to tasks

- Tailored conformance

- Normative references

- Terms, definitions, and abbreviated terms

- Terms and definitions

- Abbreviated terms

- Key concepts and application of this International Standard

- Introduction

- System concepts

- Systems

- System structure

- Enabling systems

- Organization and project concepts

- Organizations

- Organization and project-level adoption

- Life cycle concepts

- System life cycle model

- System life cycle stages

- Process concepts

- Criteria for processes

- Description of processes

- General characteristics of processes

- Tailoring

- Processes in this standard

- Introduction

- Agreement processes

- Organizational project-enabling processes

- Technical management processes

- Technical processes

- Process application

- Process reference model

- System life cycle processes

- Agreement processes

- Acquisition process

- Supply process

- Organizational project-enabling processes

- Life cycle model management process

- Infrastructure management process

- Portfolio management process

- Human resource management process

- Quality management process

- Knowledge management process

- Technical management processes

- Project Planning Process

- Project assessment and control process

- Decision management process

- Risk management process

- Configuration management process

- Information management process

- Measurement process

- Quality assurance process

- Technical processes

- Business or mission analysis process

- Stakeholder needs and requirements definition process

- System requirements definition process

- Architecture definition process

- Design definition process

- System analysis process

- Implementation process

- Integration process

- Verification process

- Transition process

- Validation process

- Operation process

- Maintenance process

- Disposal process

- Agreement processes

- Annex A (normative): Tailoring Process

- Introduction

- Tailoring process

- Purpose

- Outcomes

- Activities and tasks

- Annex B (informative): Example process information items

- Introduction

- Annex C (informative): Process reference model for assessment purposes

- Introduction

- Conformance with ISO/IEC 15504-2

- General

- Requirements for process reference models

- Process descriptions

- The process reference model

- Annex D (informative): Process integration and process constructs

- Introduction

- Process constructs and their usage

- Annex E (informative) Process views

- Introduction

- The process view concept

- Process viewpoint

- Process view for specialty engineering

- Process view for interface management

- Annex F (Informative): Architecture modeling

- Introduction

- Viewpoints, views and model kinds used in architecture

- Logical and physical models

- Functional model

- Behavioural model

- Temporal model

- Structural model

- Mass model

- Layout model

- Network model

- Other model considerations

- Annex G (Informative) Application of system life cycle processes to a system of systems

An Example of Course Syllabus Preparation for Introduction to Industrial Systems Engineering (ISO/IEC/IEEE 15288:2015(E)

Course Code-XYZ 1234 – Introduction to Industrial Systems Engineering

Syllabus:

Products, services and processes are designed and developed in an increasingly complex industrial system. Therefore, system thinking is important in modern production. This course presents framework based on system engineering processes that will be used for planning, analysis, and design of industrial systems, such as products, manufacturing plants, operational processes, information systems, and supply chains. Major introduction to the system’s stages along with its life cycle will be given, with the main focus on system design, beginning from conceptual design to production. The main topics in this course are set out in accordance with ISO/IEC/IEEE 15288:2015(E) as follows:

- System concepts

- Organization and project concepts

- Life cycle concepts

- Process concepts

- Process application

- Process reference model

System life cycle processes:

- Agreement processes

- Acquisition process

- Supply process

- Organizational project-enabling processes

- Life cycle model management process

- Infrastructure management process

- Portfolio management process

- Human resource management process

- Quality management process

- Knowledge management process

- Technical management processes

- Project Planning Process

- Project assessment and control process

- Decision management process

- Risk management process

- Configuration management process

- Information management process

- Measurement process

- Quality assurance process

- Technical processes

- Business or mission analysis process

- Stakeholder needs and requirements definition process

- System requirements definition process

- Architecture definition process

- Design definition process

- System analysis process

- Implementation process

- Integration process

- Verification process

- Transition process

- Validation process

- Operation process

- Maintenance process

- Disposal process

Furthermore, Analytical Methods, Reference Models, and Key Performance Indicators at each stage of the system are discussed.

Note: All methods of quantitative analysis are integrated directly into the discussion of the stages throughout the system’s life cycle

Learning Outcome:

This course covers an understanding of sustainability and how environmental aspects can be integrated into system design.

Knowledge:

At the end of this course, students will be: (1) ABLE to explain the relationship between Systems Thinking and Systems Engineering; (2) ABLE to explain how the V-model (see the accompanying charts above and below) provides a roadmap for systems engineering practice; (3) ABLE to apply systems engineering practice to a project; and (4) ABLE to evaluate a project based on the quality of its process.

Skills:

At the end of this course, students will be ABLE to (1) identify and apply systems thinking habits; (2) identify and document the elements of the system as well as the interactions and interrelationships between the elements of the system; (3) design the layout of the factory or production process; and, (4) critically assess the quality of the engineering of a system.

General Competency (Attitude):

At the end of this course, students will be able to (1) apply knowledge of industrial systems engineering in a project that requires multidisciplinary and multicultural teamwork; (2) track progresses, risks and ongoing risk mitigation activities; and, (3) communicate and explain the contribution of systems engineering to systems development.

If all courses from Higher Education in Indonesia are structured in integrated manner to establish MINIMUM COMPETENCY standards within the specific area of knowledge, and their syllabi follow international standards, then Higher Education graduates in Indonesia will be able to compete in global (national, regional and international) markets. In this case, for example, Industrial Systems Engineering graduates from Educational institutions in Papua, NTT, Kalimantan, Java, Sumatra, etc., will have the same MINIMUM COMPETENCY with graduates from industrial systems engineering disciplines from Malaysia, Singapore, Australia, Canada, USA, etc., because all those higher education institutions have been referring to international standards. Currently there has been a new term of being Glocal (Thinking Globally, Acting Locally). Otherwise, if the higher education in Indonesia remains the same, the cosmopolitan public expression of standardization, namely: “Thinking Globally, Acting Locally” will be interpreted at will and may instead be interpreted at worse to “Thinking Locally, Acting Kampungan/Plebeianly”.

References List:

- Badiru, A. B., 2014. Handbook of Industrial and Systems Engineering, 2nd ed., CRC Press, Florida., xiii+1.271 pages

- Garvey, P. R., 2009., Analytical Methods for Risk Management: A Systems

Engineering Perspective., CRC Press, New York, xviii + 264 pages. - ISO/IEC/IEEE 15288:2015(E). Systems and Sopftware Engineering—System Life Cycle Processes., ISO., Switzerland.

- Kossiakoff, A., William N. Sweet, Samuel J. Seymour, and Steven M. Biemer., 2011. Systems Engineering Principles and Practices, 2nd ed., John Wiley & Sons, New Jersey, xxii + 526 pages.